Sputtering targets are the beating heart of any vacuum coating system. Whether you’re involved in the semiconductor industry, optical coatings, or advanced materials research, the performance of your thin film deposition process hinges on the quality and condition of your sputtering target. But like any consumable component, sputtering targets don’t last forever.

Knowing when to replace a sputtering target is crucial for maintaining film quality, optimizing deposition rates, and avoiding costly downtime. Replacing it too early wastes materials and money; replacing it too late risks damaging your equipment or ruining batches.

In this comprehensive guide, we explore five key indicators that it’s time to replace your sputtering target, blending practical advice with scientific insight. This article is designed to help process engineers, lab technicians, and production managers make informed decisions backed by experience and observable data.

1. Uneven Erosion or Target Burn-Through

One of the most visible and commonly cited signs that your sputtering target needs replacing is uneven erosion or the formation of an erosion “trough.” During the magnetron sputtering process, plasma confinement causes erosion to concentrate in specific regions, forming racetrack-like patterns over time.

If left unchecked, these patterns deepen until they compromise the mechanical integrity of the target, potentially causing burn-through.

Signs to Watch For:

- Racetrack formation that is visibly deep or off-centered.

- Localized thinning of the target material.

- Exposure of backing plate due to severe erosion.

- Arc events or plasma instability during sputtering.

Why It Matters:

Continued use of an eroded target increases the risk of electrical arcing, non-uniform film deposition, and even vacuum contamination. In systems with bonded sputtering targets, extreme erosion can weaken the bond and damage the backing plate, making the entire assembly unusable.

Tip: Regularly inspect your targets and maintain records of erosion depth and uniformity. Using profilometry tools or laser scanning can provide a precise erosion map.

Relevant Keywords: sputtering target erosion, magnetron sputtering wear, thin film uniformity.

2. Reduced Deposition Rates

A well-functioning target should provide predictable and repeatable deposition rates under the same conditions. If you begin to notice a gradual decline in deposition rate, despite consistent power, pressure, and substrate distance, your target may be nearing the end of its usable life.

Causes of Deposition Rate Drop:

- Low remaining material thickness near the racetrack.

- Target poisoning in reactive sputtering systems.

- Increased resistivity of aged or oxidized targets.

- Poor thermal conductivity due to erosion or delamination.

How to Monitor It:

Using a quartz crystal microbalance (QCM) or optical thickness monitor, measure the deposition rate regularly. Any significant decline, especially in high-throughput environments, is a red flag. If the rate drops more than 10-15% compared to the baseline, it’s time to consider replacing the target.

Important Note: Reduced deposition efficiency doesn’t just impact productivity—it can also affect the film density, adhesion, and stoichiometry, which are critical in electronics and optics applications.

Relevant Keywords: sputtering target life, vacuum coating process control, thin film deposition monitoring.

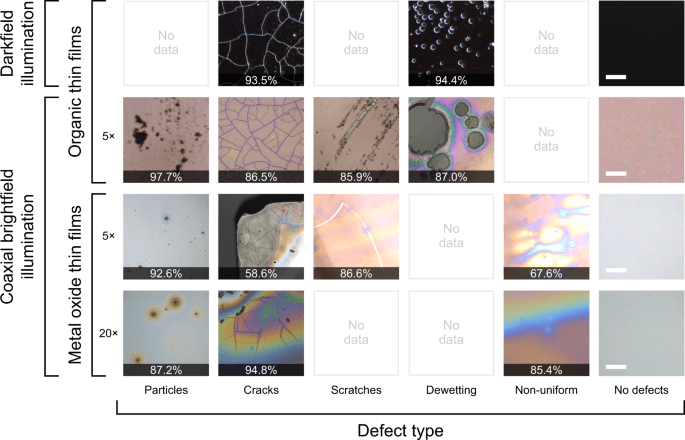

3. Film Quality Issues or Inconsistent Coating Results

A sputtering system is only as good as the quality of its coatings. One of the most subtle yet costly signs that your sputtering target needs replacement is a drop in film quality. This can show up as:

- Non-uniform thickness across the substrate.

- Pinholes, particulates, or surface defects in the film.

- Color shifts in optical coatings.

- Electrical performance deviations in semiconductor layers.

- Peeling or poor adhesion.

Root Causes:

- Contaminants embedded in or released by an old target.

- Backsputtering from an uneven or degraded target surface.

- Plasma instability due to irregular erosion profiles.

- Microscopic cracks or delamination within the target-bonding layer.

In high-precision applications like dielectric coatings, solar cell manufacturing, or data storage films, even slight changes in deposition consistency can result in failed products or batch rework.

Expert Insight: If you’re frequently recalibrating or adjusting parameters to maintain film specs, don’t just look at the process—inspect the target.

Relevant Keywords: sputtered film defects, vacuum coating quality control, thin film failure analysis.

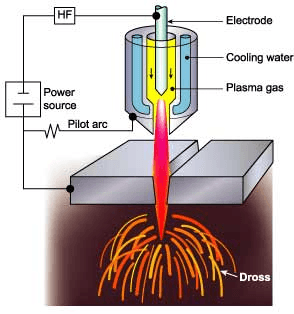

4. Arcing and Electrical Instability

As a sputtering target nears the end of its life, it often becomes prone to electrical arcing, especially in high-power applications or reactive sputtering environments (e.g., with oxygen or nitrogen).

Arcing occurs when the plasma becomes unstable, and a sudden discharge of energy jumps across a non-conductive gap, typically due to surface irregularities, oxidized layers, or contaminant buildup on the target.

Warning Signs:

- Sudden spikes in voltage or current during operation.

- Discolored or cracked films.

- Plasma extinguishing or pulsing.

- Unusual noises or arcs visible inside the chamber.

Consequences of Ignoring Arcing:

- Damage to power supply or matching network.

- Formation of defects in the coating.

- Increased chamber maintenance due to debris or flakes.

- Reduced target material utilization efficiency.

Using pulsed DC or RF power supplies can help minimize arcing in some cases, but persistent instability often signals a deeper issue—like target burnout or contamination.

Tip: Always ground-check your target and inspect for oxide layers or delamination before restarting after an arc.

Relevant Keywords: sputtering arc prevention, target surface contamination, power instability during deposition.

5. Target Delamination or Bonding Failures

In bonded targets—especially for high-melting-point metals like tantalum, molybdenum, or titanium—the bonding interface between the target and backing plate is essential for thermal management. As the target wears, thermal cycling can cause:

- Cracking or delamination between the target and the backing plate.

- Warping or bowing of the target face.

- Hot spots leading to target fractures or uneven sputtering.

Signs of Bonding Failure:

- Excessive heat or burning marks near the target.

- Audible popping sounds during ramp-up.

- Sudden increase in base pressure after shutdown.

- Film inconsistencies correlated with thermal hotspots.

Target bonding failure is particularly dangerous because it affects the thermal conductivity, which is essential for dissipating the heat generated during sputtering. Poor heat transfer can cause both immediate equipment damage and long-term film quality degradation.

Pro Tip: If you suspect a bond failure, use infrared imaging to spot thermal inconsistencies during deposition runs.

Relevant Keywords: bonded sputtering target failure, heat transfer in sputtering, target delamination symptoms.

When in Doubt, Use Predictive Maintenance Tools

Rather than waiting for signs of failure, many facilities now use predictive maintenance strategies to track target health. These include:

- Erosion profiling after each batch.

- Cycle-counting with automated alerts based on process runtime.

- Thermal sensors for detecting overheating.

- Chamber vacuum behavior analysis post-deposition.

Predictive maintenance doesn’t just prevent failure—it improves cost-efficiency and allows for better inventory planning of spare targets.

Relevant Keywords: predictive maintenance in PVD systems, sputtering equipment lifecycle, vacuum chamber monitoring.

Summary: Don’t Wait for Failure—Act on the Signs

Replacing a sputtering target may seem like a routine task, but it’s one with critical implications. A worn-out target affects not only deposition rates and coating quality but also the safety and efficiency of your vacuum coating system. Recognizing the early signs of target wear—uneven erosion, deposition rate drop, coating defects, electrical instability, and bonding failure—can help you avoid costly repairs and production setbacks.

Make it a practice to visually inspect, measure, and record the performance metrics of your sputtering targets. By doing so, you build a reliable history that can inform your decisions and streamline your coating operations.

Whether you’re using molybdenum sputtering targets, tantalum targets, or specialty alloys, keeping your system in top shape starts with knowing when it’s time for a change.

Final Thoughts: Proactive Target Replacement Saves Time and Quality

Knowing when to replace your sputtering target is more than just a technical decision—it’s a strategic one. Regular inspection, deposition rate tracking, and attention to film consistency can prevent system failures, minimize downtime, and ensure the reliability of your thin film coatings.

If you’re seeing signs like deep erosion tracks, plasma arcing, reduced deposition rates, or film defects, don’t wait for catastrophic failure. Instead, consult with your thin film materials supplier, analyze your process metrics, and plan for timely target replacement.

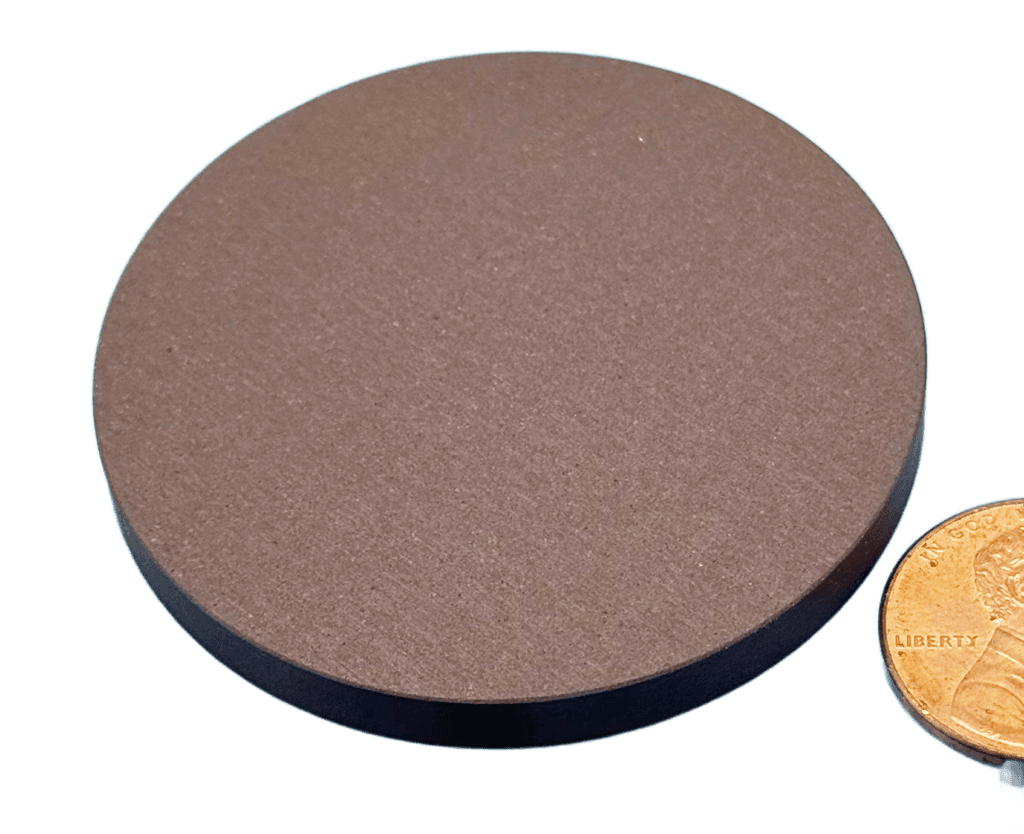

At TFM (Thin Film Materials), we supply a wide range of sputtering targets and vacuum coating components trusted across industries—from semiconductors to optics. Here are some of our most popular products that can support your process:

🔹 Featured Sputtering Targets and Vacuum Coating Components from TFM:

- High Purity Gold (Au) Sputtering Target – Ideal for precision electronics and optical coatings.

- ITO (Indium Tin Oxide) Sputtering Target – Widely used in transparent conductive films.

- Titanium (Ti) Sputtering Target – Common for barrier and adhesion layers.

- Silicon (Si) Sputtering Target – For semiconductor and dielectric thin film applications.

- Molybdenum (Mo) Sputtering Target – Known for high thermal stability and adhesion control.

- Target Bonding Service – Ensures excellent thermal conductivity and longer target life.

- ConFlat Flanges and Components – Precision machined UHV-compatible vacuum hardware.

- Quartz Viewports – KF Flange Type – Perfect for real-time optical monitoring in vacuum systems.

We understand that no two sputtering processes are exactly alike. That’s why our engineering team is ready to help you find the right target material, purity, bonding, and size for your specific coating system.