Antimony Sputtering Target Description

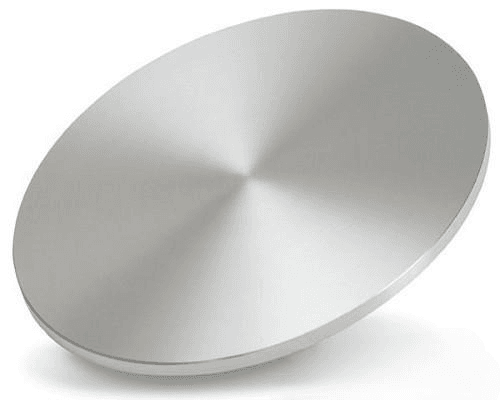

Antimony Sputtering Targets, composed of the semi-metallic element antimony, play a crucial role in thin-film deposition processes. These silvery-gray materials have applications in semiconductor manufacturing, electronics, and various coating technologies. Antimony has a fascinating history, with its compounds being used in ancient times for medicinal and cosmetic purposes, often known by an Arabic name. The element’s discovery in the West was initially marked by misidentification, but it was eventually correctly described in the mid-sixteenth century.

Modern industrial methods for refining antimony involve roasting and reduction processes, typically using carbon or iron. The resulting high-purity antimony is then fashioned into sputtering targets, essential in creating thin films for electronic components, optical coatings, and wear-resistant materials. Antimony’s unique properties make it well-suited for sputtering applications, allowing for efficient deposition under various power conditions. This versatile element continues to be an important material in advanced manufacturing and materials science.

Antimony Sputtering Target Specification

| Material Type | Antimony |

| Symbol | Sb |

| Color/Appearance | Silvery, Lustrous Gray, Semi-metallic |

| Melting Point | 630 °C |

| Sputter | RF, DC |

| Density | 6.68 g/cc |

| Thermal Conductivity | 24 W/m.K |

| Type of Bond | Indium, Elastomer |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Antimony Sputtering Target Applications

Antimony sputtering targets are essential for creating fire-retardant materials and enhancing safety in commercial and household products. Antimony compounds, especially antimony trichloride, contribute functional and aesthetic properties in flame-resistant formulations, specialized paints, ceramic enamels, and the glass and pottery industries.

Antimony improves the hardness and strength of lead alloys in metallurgy, making them ideal for durable components like ball bearings. This versatility highlights antimony’s crucial role in modern manufacturing, from boosting product safety to enhancing metal alloy performance.

Antimony Sputtering Target Bonding Services

Specialized bonding services for Antimony Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Our Antimony Sputter Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage and transportation.

Get Contact

TFM offers Antimony Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

MSDS File

MSDS File

Reviews

There are no reviews yet.