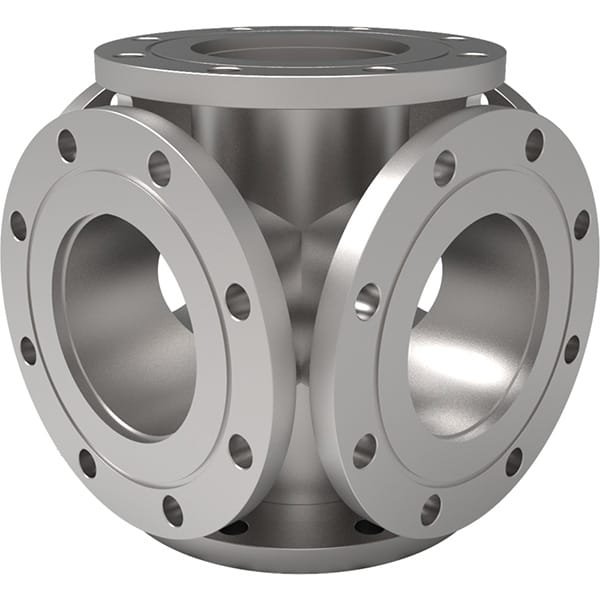

ASA HV 6-Way Crosses (grooved flanges): All-Grooved Flange Design for Consistent High-Vacuum Sealing

ASA HV 6-Way Crosses (grooved flanges) from TFM are precision-fabricated components built for demanding high-vacuum (HV) environments, offering six-way connectivity with a uniform sealing interface. Each cross is manufactured from corrosion-resistant 304L stainless steel tubing and features rotatable ASA flanges with grooves on all six ports. This design enables reliable sealing when mated with flat ASA flanges using elastomeric o-rings.

The grooved ASA flanges follow the traditional sexed vacuum sealing method, where the groove accommodates the o-ring and the mating flat flange compresses it to create a vacuum-tight seal. These crosses are particularly suited for setups where consistent grooved interfaces are required across multiple directions for integration with flat-faced chamber ports, valves, or extensions.

Key Features of ASA HV 6-Way Crosses (grooved flanges):

Uniform Grooved ASA Flange Configuration

All six axes are equipped with rotatable grooved ASA flanges, ensuring compatibility with flat mating flanges and simplifying the use of standard ASA o-ring sealing assemblies.304L Stainless Steel Construction

Delivers high structural integrity and corrosion resistance, suitable for both industrial and research-grade high-vacuum systems operating at pressures down to 10⁻⁸ Torr.Rotatable Flange Design

Enables easier alignment during installation and system integration, especially in tight or complex layouts.Leak-Tight Performance

Each ASA HV 6-Way Cross (grooved flanges) is helium leak tested and cleaned to vacuum service standards, ensuring reliable sealing and low outgassing.Available in Standard and Custom Sizes

TFM offers sizes including ASA 4″, 6″, 8″, 10″, and 12″, with options for custom tube lengths, wall thicknesses, or port reducers upon request.

Common Applications:

Central distribution hubs in high-vacuum chambers

Multi-port gas handling or exhaust systems

Pumping, measurement, and diagnostics nodes

Retrofit expansions in ASA-standard infrastructure

Custom modular vacuum assembly configurations

TFM also supplies the full range of supporting hardware, including ASA bolt sets, fluorocarbon (FKM) o-rings, blank flanges, and adapter flanges, allowing for complete and secure installation with minimal assembly time.

In summary, ASA HV 6-Way Crosses (grooved flanges) provide a consistent, high-integrity sealing solution for advanced vacuum systems. Their all-grooved configuration ensures compatibility with flat ASA flanges, while their stainless steel construction and rotatable design offer long-lasting performance and installation flexibility.

Ordering Table

Reviews

There are no reviews yet.