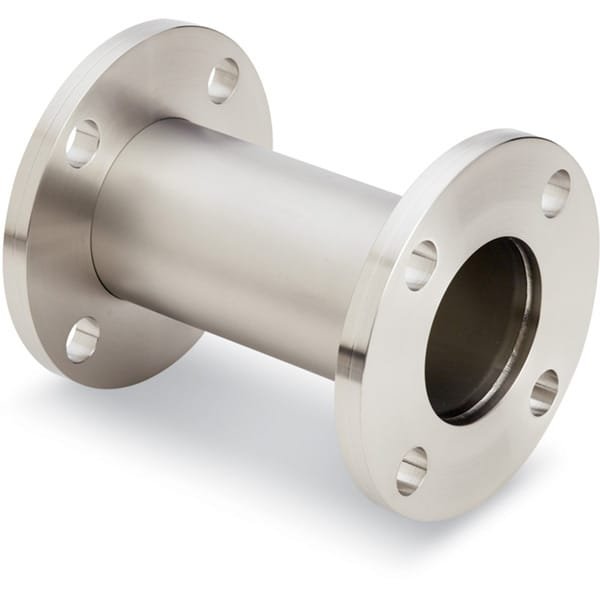

ASA HV Standard Full Nipples (Flat Flanges): Reliable Pipeline Extensions for ASA Grooved Flange Interfaces

ASA HV Standard Full Nipples (Flat Flanges) from TFM are designed to provide straight, durable connections in high-vacuum (HV) systems using the ASA sealing standard. These full-length spools are fabricated from 304L stainless steel tubing and feature two rotatable flat ASA flanges, making them ideal for integration with grooved flange components.

Flat ASA flanges compress against o-ring-retaining grooved flanges to form secure, sexed vacuum seals. This configuration supports flexible assembly and consistent sealing performance in systems operating at pressures as low as 10⁻⁸ Torr, ensuring reliability in demanding scientific and industrial applications.

Key Features of ASA HV Standard Full Nipples (Flat Flanges):

Dual Flat ASA Flanges

Designed to mate with grooved ASA flanges using elastomeric o-rings for repeatable, high-integrity vacuum seals.304L Stainless Steel Construction

Offers strong corrosion resistance and mechanical stability, suitable for thermal cycling and chemically reactive HV environments.Rotatable Flanges for Easy Alignment

Each flange is rotatable to support flexible orientation and simplified installation in tight or complex assemblies.Straight Through Spool Design

Facilitates uninterrupted vacuum flow between aligned flanged components, ideal for pipeline extension or system modularity.Vacuum-Grade Manufacturing

Helium leak tested and cleaned for high-vacuum compatibility; suitable for research labs, semiconductor tools, and general HV infrastructure.Available in Standard and Custom Configurations

Offered in standard ASA flange sizes like 4″, 6″, 8″, 10″, and 12″, with custom tube lengths, wall thicknesses, and flange options available upon request.

Typical Applications:

Connecting ASA grooved-flange equipment in HV systems

Foreline extensions or straight-through vacuum plumbing

Chamber-to-valve or pump interconnections

Retrofitting vacuum assemblies with o-ring-sealed flat flange interfaces

Research, aerospace, and high-purity process vacuum configurations

TFM also supplies grooved ASA flanges, FKM/Buna-N o-rings, bolt kits, and custom transition fittings to support complete ASA-standard system builds.

In summary, ASA HV Standard Full Nipples (Flat Flanges) provide a robust and adaptable solution for extending vacuum pipelines or joining ASA grooved flange interfaces. Their dual-flat design, stainless steel strength, and vacuum-ready fabrication make them ideal for precision vacuum applications.

Reviews

There are no reviews yet.