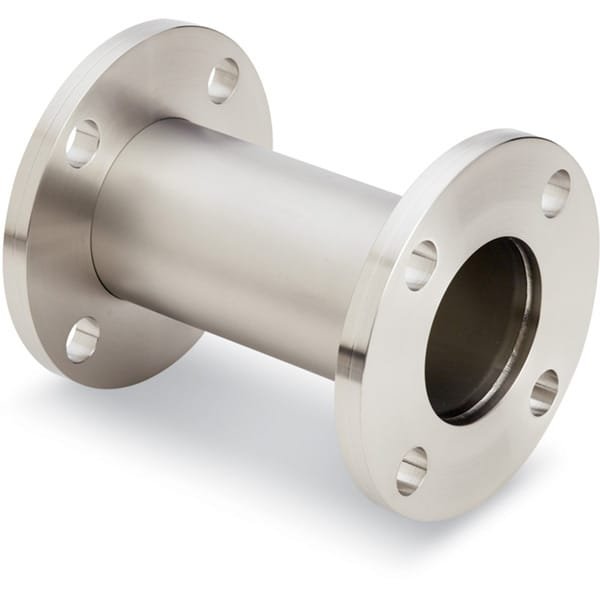

ASA HV Standard Full Nipples (Grooved Flanges): Dual-Grooved Vacuum Nipples for ASA O-Ring Sealing Interfaces

ASA HV Standard Full Nipples (Grooved Flanges) from TFM are designed to deliver robust and leak-tight straight-line connections between ASA-standard components in high-vacuum (HV) systems. Fabricated using 304L stainless steel tubing, these full nipples feature exceptional mechanical strength, corrosion resistance, and vacuum cleanliness.

Each unit is equipped with two rotatable grooved ASA flanges, making them ideal for mating with flat ASA flanges in accordance with sexed ASA sealing standards. The grooves are precisely machined to seat elastomeric o-rings, ensuring secure compression when bolted against flat mating surfaces.

This configuration is perfect for systems built around o-ring sealed ASA flanges, offering both structural continuity and consistent vacuum performance.

Key Features of ASA HV Standard Full Nipples (Grooved Flanges):

Dual Grooved ASA Flanges

Designed for mating with flat ASA flanges using elastomeric o-rings, supporting vacuum operation down to 10⁻⁸ Torr or lower.304L Stainless Steel Construction

Provides high corrosion resistance, weldability, and durability under thermal cycling—essential for demanding high-vacuum processes.Rotatable Flanges for Installation Flexibility

Both grooved flanges are rotatable to simplify alignment and assembly, especially in tight or modular layouts.Straight, Full-Length Spool Design

Ideal for creating rigid, leak-tight interconnections between ASA-flanged components without directional change.Leak Tested and Vacuum Cleaned

All ASA HV Standard Full Nipples (Grooved Flanges) are helium leak tested and prepared to vacuum-grade cleanliness.Standard and Custom Options Available

Available in common ASA sizes (4″, 6″, 8″, 10″, 12″), with customizable tube lengths, wall thicknesses, and flange size combinations upon request.

Applications:

Vacuum line extension between grooved-to-flat ASA flange interfaces

Interconnection of pumps, chambers, or gauges in ASA-based HV systems

O-ring sealed straight-line routing in foreline or exhaust paths

Modular vacuum infrastructure in research, semiconductor, or aerospace environments

Retrofit or expansion of existing ASA vacuum assemblies

TFM also provides flat ASA flanges, o-rings (FKM, Buna-N), bolt kits, and matching reducer fittings for seamless system integration.

In summary, ASA HV Standard Full Nipples (Grooved Flanges) offer a straightforward and secure solution for extending or linking ASA-standard vacuum components with o-ring sealing. Their robust design, precision fabrication, and compatibility with grooved sealing conventions make them a dependable choice for any HV system requiring structural and vacuum-tight continuity.

Reviews

There are no reviews yet.