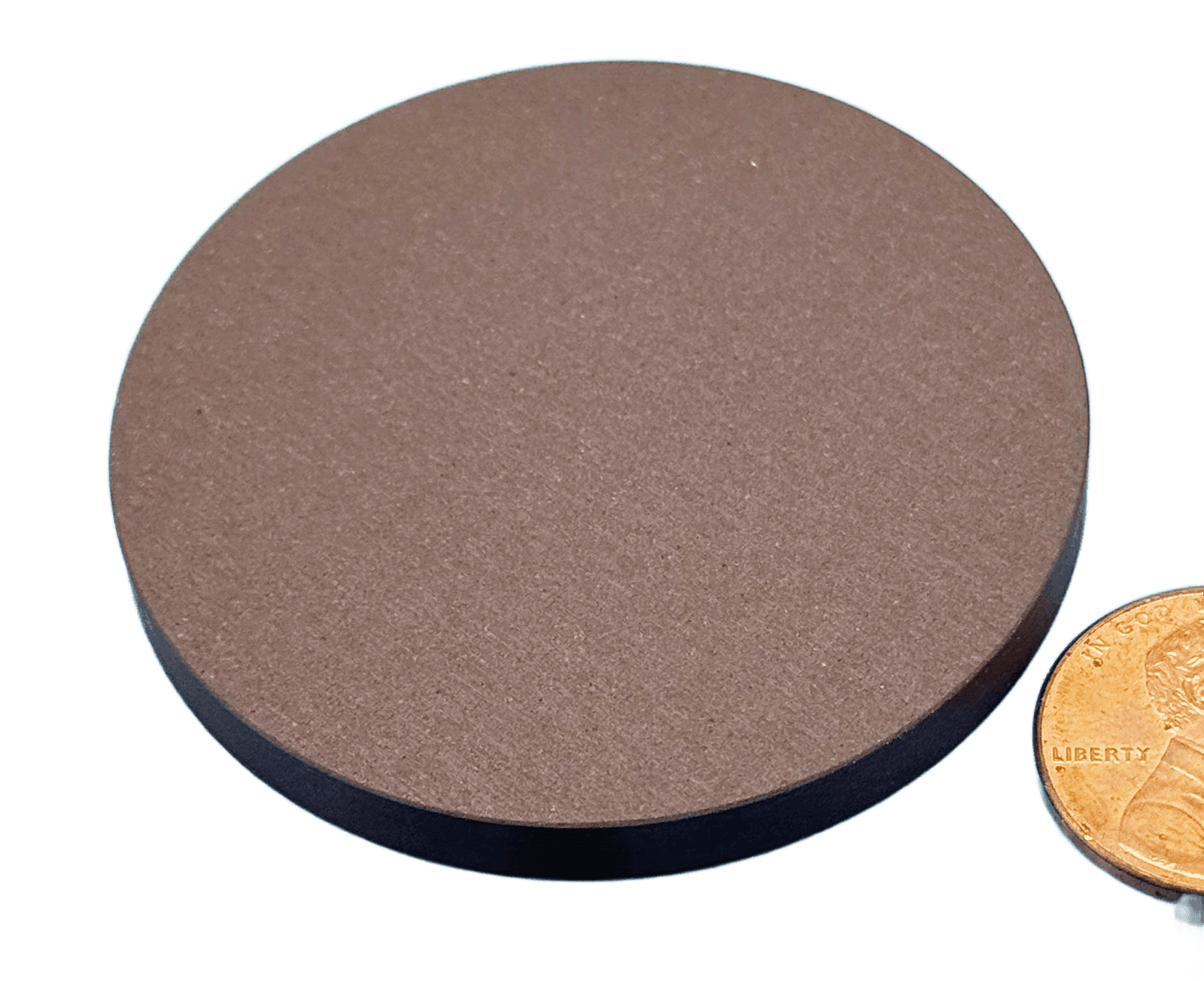

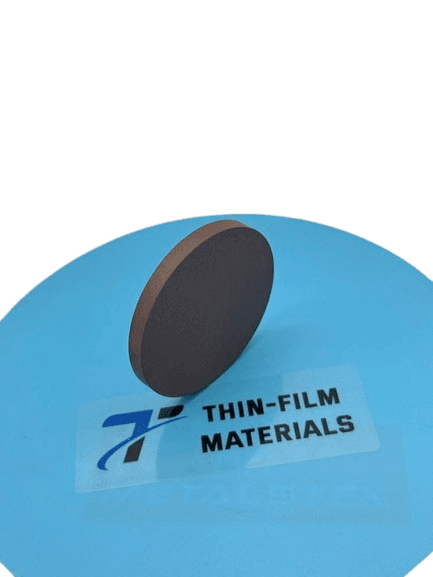

Bismuth Ferrite Sputtering Target Description

The Bismuth Ferrite Sputtering Target from TFM is an oxide sputtering material with the chemical formula BiFeO3.

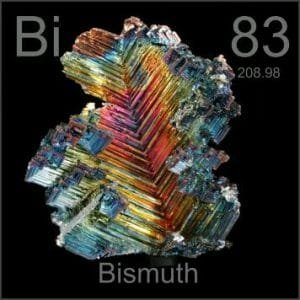

Bismuth is a chemical element whose name originates from the German word ‘Bisemutum,’ a corruption of ‘Weisse Masse,’ meaning white mass. It was first used in 1753 and discovered by C.F. Geoffroy. The chemical symbol for bismuth is “Bi,” and its atomic number is 83. Bismuth is located in Period 6, Group 15 of the periodic table, within the p-block. Its relative atomic mass is 208.98040(1) Dalton, with the number in brackets indicating the measurement uncertainty.

Bismuth is a chemical element whose name originates from the German word ‘Bisemutum,’ a corruption of ‘Weisse Masse,’ meaning white mass. It was first used in 1753 and discovered by C.F. Geoffroy. The chemical symbol for bismuth is “Bi,” and its atomic number is 83. Bismuth is located in Period 6, Group 15 of the periodic table, within the p-block. Its relative atomic mass is 208.98040(1) Dalton, with the number in brackets indicating the measurement uncertainty.

Related Product: Bismuth (Bi) Sputtering Target

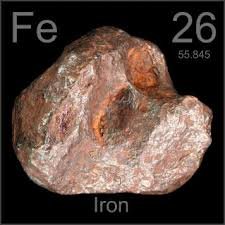

Iron, also known as ferrum, is a chemical element with its name originating from the Anglo-Saxon word “iren” and the Latin word “ferrum.” It has been used since before 5000 BC. The chemical symbol for iron is “Fe,” and it has an atomic number of 26. Iron is located in Period 4, Group 8 of the periodic table, within the d-block. Its relative atomic mass is 55.845(2) Dalton, with the number in parentheses indicating the measurement uncertainty.

Iron, also known as ferrum, is a chemical element with its name originating from the Anglo-Saxon word “iren” and the Latin word “ferrum.” It has been used since before 5000 BC. The chemical symbol for iron is “Fe,” and it has an atomic number of 26. Iron is located in Period 4, Group 8 of the periodic table, within the d-block. Its relative atomic mass is 55.845(2) Dalton, with the number in parentheses indicating the measurement uncertainty.

Related Product: Iron (Fe) Sputtering Target

Oxygen is a chemical element that originated from the Greek ‘oxy’ and ‘genes’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele. The isolation was later accomplished and announced by W. Scheele. “O” is the canonical chemical symbol of oxygen. Its atomic number in the periodic table of elements is 8 with a location at Period 2 and Group 16, belonging to the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, the number in the brackets indicating the uncertainty.

Oxygen is a chemical element that originated from the Greek ‘oxy’ and ‘genes’ meaning acid-forming. It was first mentioned in 1771 and observed by W. Scheele. The isolation was later accomplished and announced by W. Scheele. “O” is the canonical chemical symbol of oxygen. Its atomic number in the periodic table of elements is 8 with a location at Period 2 and Group 16, belonging to the p-block. The relative atomic mass of oxygen is 15.9994(3) Dalton, the number in the brackets indicating the uncertainty.

Bismuth Ferrite Sputtering Target Application

The Bismuth Ferrite Sputtering Target is utilized in various applications, including thin film deposition, decorative coatings, semiconductors, displays, LEDs, and photovoltaic devices. It is also essential for functional coatings, the optical information storage industry, glass coatings for automotive and architectural glass, and optical communication systems, among other fields.

Bismuth Ferrite Sputtering Target Packing

Our Bismuth Ferrite Sputtering Targets are meticulously tagged and labeled externally to ensure efficient identification and stringent quality control. We take extensive precautions to prevent any damage during storage and transportation, maintaining the highest standards of product integrity upon delivery.

MSDS File

MSDS File

Reviews

There are no reviews yet.