Calcium Oxide Sputtering Target Description

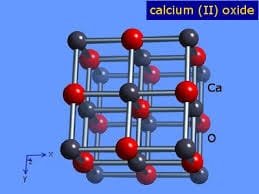

Calcium Oxide is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term “lime” connotes calcium-containing inorganic materials, in which carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminum, and iron predominate. In contrast, “quicklime” specifically refers to the single chemical compound calcium oxide.

Related Products: Calcium Sputtering Target

Manufacturing Process

- Manufacturing

- Cold Pressing: High-purity materials are formed into the desired shape and size by cold pressing.

- Sintering: The pressed materials are sintered at high temperatures to increase density and mechanical strength.

- Elastomer Bonding: The sintered target is elastomer-bonded to a backing plate for enhanced stability and durability during use.

- Cleaning and Final Packaging

- Cleaning: The sputtering targets are meticulously cleaned to ensure they are suitable for vacuum environments and free from contaminants.

- Protection from Environmental Contaminants: Steps are taken to safeguard the targets from environmental contaminants that could affect their performance.

- Protection During Shipment: The targets are carefully packaged to prevent any damage during transportation, ensuring they arrive in perfect condition for use.

Calcium Oxide Sputtering Target Specification

| Material Type | Calcium Oxide |

| Symbol | CaO |

| Color/Appearance | White Target |

| Melting Point | 2,572° C(4,662° F) |

| Sputter | RF-R |

| Density | 3.3 g/cm3 |

Packing

Our calcium oxide sputtering target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage that might occur during storage or transportation, ensuring the product arrives in perfect condition.

Get Contact

TFM offers Calcium Oxide Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.