Cerium Sputtering Target Description

Cerium Sputtering Target Specification

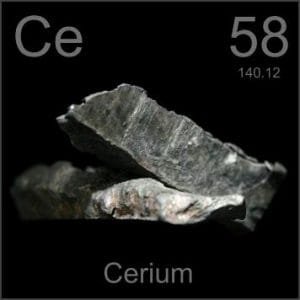

| Material Type | Cerium |

| Symbol | Ce |

| Color/Appearance | Silvery White, Metallic |

| Melting Point | 798°C |

| Density | ~6.70g/cc |

| Thermal Conductivity | 1 W/m.K |

| Coefficient of Thermal Expansion | 6.3 x 10-6/K |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Cerium Sputtering Target Application

Cerium sputtering targets are used for:

- Manufacturing aluminum alloys and certain steels and irons

- Preventing graphitization in cast iron, producing malleable iron

- Removing sulfides and oxides in steel, achieving complete detoxification

- Serving as a precipitation-hardening agent in stainless steel

Handling Notes

- Bonding services for cerium sputtering targets are currently unavailable.

- Due to its high chemical reactivity, cerium sputtering targets require oil packaging and thorough cleaning to prevent environmental reactions.

Get Contact

TFM offers Cerium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.