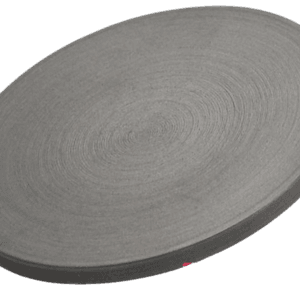

Cobalt Manganese Gallium Sputtering Target

Introduction

The Cobalt Manganese Gallium Sputtering Target (Co-Mn-Ga) is a specialized alloy target designed for advanced thin film deposition. Known for its unique magnetic and electronic properties, this material is particularly valued in the development of spintronic devices, magneto-optical applications, and next-generation semiconductor research. By precisely controlling the alloy composition, researchers and engineers can tailor thin film characteristics for highly specialized functionalities.

Detailed Description

Cobalt Manganese Gallium belongs to the class of Heusler alloys, which exhibit half-metallic ferromagnetism and tunable electronic structures. When fabricated into sputtering targets, the material maintains high density and uniform microstructure, ensuring stable deposition rates and reproducible thin film quality.

Key features include:

Composition Control: Typically produced with atomic ratios such as Co₂MnGa, enabling half-metallic behavior.

High Purity: Available in 99.9%–99.99% purity grades to minimize contamination during thin film deposition.

Custom Dimensions: Supplied as discs, plates, or rectangular targets ranging from laboratory-scale to large-area coating systems.

Optional Bonding: Copper or titanium backing plates are available to enhance thermal conductivity and improve target stability during high-power sputtering.

These properties make the Co-Mn-Ga sputtering target an essential material for both academic research and industrial applications where precise magnetic and electronic performance is required.

Applications

Spintronics: Fabrication of magnetic tunnel junctions (MTJs), spin valves, and spin-transfer torque devices.

Semiconductors: Thin films for magneto-electronic integration with CMOS technology.

Optics: Development of magneto-optical coatings and sensors.

R&D: Fundamental studies on Heusler alloys, half-metallicity, and band structure engineering.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Higher purity ensures reduced impurities in magnetic films |

| Composition | Co₂MnGa (customizable) | Maintains half-metallic ferromagnetic properties |

| Diameter | 25 – 300 mm (custom) | Compatible with laboratory and industrial sputtering systems |

| Thickness | 3 – 6 mm | Affects sputtering rate and deposition uniformity |

| Bonding | Copper / Titanium backing | Enhances cooling and prevents cracking under load |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Cobalt Manganese Gallium (CoMnGa) | Half-metallic, tunable magnetism | Spintronics, MTJs |

| Cobalt Iron Aluminum (Co₂FeAl) | Stronger magnetic moments | Magnetic recording |

| Nickel Manganese Gallium (NiMnGa) | Shape-memory and magnetostriction | Actuators, sensors |

FAQ

| Question | Answer |

|---|---|

| Can the target composition be customized? | Yes, atomic ratios of Co, Mn, and Ga can be adjusted to meet specific research requirements. |

| How is it packaged? | Targets are vacuum-sealed with protective foam and shipped in export-safe cartons or wooden crates. |

| What deposition methods are supported? | Primarily DC/RF magnetron sputtering; can also be used in PVD systems. |

| Which industries use it most? | Semiconductor, spintronics research, magnetic storage, and optics. |

| Is bonding necessary? | Not always, but recommended for large targets or high-power sputtering to prevent cracking. |

Packaging

Each Cobalt Manganese Gallium Sputtering Target is carefully vacuum-sealed, labeled, and cushioned with protective foam. Export-safe cartons or wooden crates are used to ensure safe delivery and long-term storage stability.

Conclusion

The Cobalt Manganese Gallium Sputtering Target is a critical material for cutting-edge magnetic and electronic thin film applications. With its unique half-metallic properties, high purity, and customizable dimensions, it supports both experimental research and commercial production needs.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.