Gadolinium(III) Oxide Powder (Gd₂O₃)

Introduction

Gadolinium(III) Oxide Powder (Gd₂O₃) is a rare-earth compound widely used in electronics, optics, nuclear applications, and advanced ceramics. With its excellent magnetic, luminescent, and neutron-absorbing properties, Gd₂O₃ is considered a critical material in both research and industrial technologies.

Detailed Description

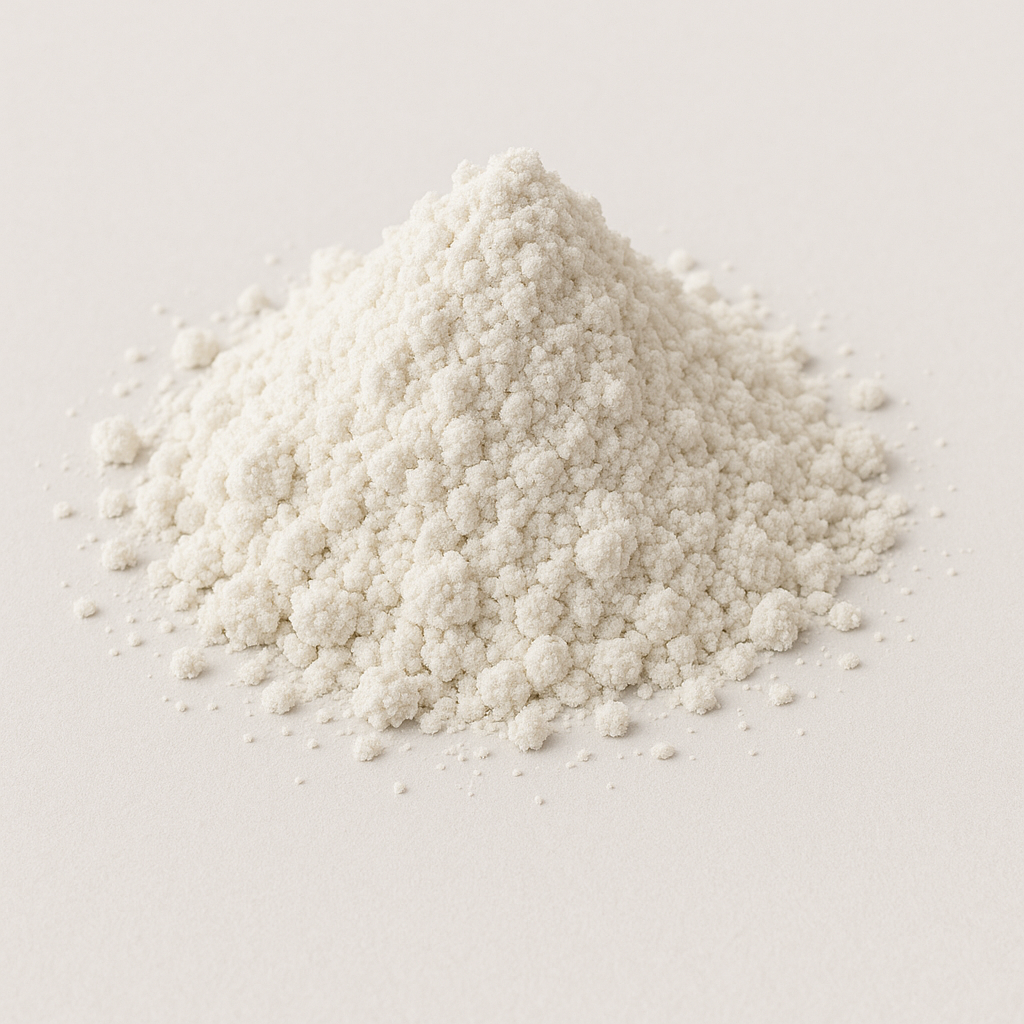

Gadolinium(III) Oxide is a white, odorless, stable powder with a high melting point (~2,420 °C) and density of ~7.41 g/cm³. It is commonly produced in high purity grades ranging from 99.9% (3N) to 99.999% (5N). The powder’s fine particle size ensures uniform sintering and high-density ceramics.

Key characteristics include:

Magnetic behavior: Gadolinium exhibits strong paramagnetism, making Gd₂O₃ essential in MRI contrast agent precursors and magneto-optical devices.

High neutron absorption cross-section: Used in nuclear reactor control materials.

Optical performance: Acts as a host material for rare-earth-doped phosphors and laser crystals.

Thermal stability: Suitable for high-temperature ceramics and coatings.

Applications

Gadolinium(III) Oxide Powder is applied in multiple industries, including:

Electronics: High-k dielectric thin films, capacitors, and memory devices.

Optics & Photonics: Phosphors, scintillators, and solid-state lasers.

Nuclear Technology: Absorber materials in reactor control rods.

Medical Imaging: Precursor for gadolinium-based MRI contrast agents.

Ceramics & Glass: Additive to improve refractive index and durability.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Ensures optical clarity and magnetic reliability |

| Particle Size | 100 nm – 5 µm | Smaller particles improve sintering behavior |

| Appearance | White fine powder | Indicates high purity and stability |

| Melting Point | ~2,420 °C | High-temperature applications |

| Density | ~7.41 g/cm³ | Important for ceramics and nuclear materials |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Gadolinium Oxide (Gd₂O₃) | Magnetic & neutron absorption | Nuclear, MRI, optics |

| Yttrium Oxide (Y₂O₃) | High transparency & stability | Optical ceramics, coatings |

| Cerium Oxide (CeO₂) | Strong redox & polishing ability | Catalysts, glass polishing |

FAQ

| Question | Answer |

|---|---|

| What purity levels are available? | 99.9% (3N), 99.99% (4N), and 99.999% (5N). |

| Can Gd₂O₃ be used in nuclear reactors? | Yes, due to its high neutron absorption properties. |

| Is it suitable for medical use? | Yes, as a precursor for MRI contrast agents, but requires further processing. |

| How is it packaged? | Vacuum-sealed in bottles or bags, larger quantities in export-grade drums. |

| Which industries benefit the most? | Electronics, optics, nuclear, medical imaging, and ceramics. |

Packaging

Gadolinium(III) Oxide Powder is packed in moisture-proof, airtight containers to preserve purity. For bulk orders, sealed drums or cartons with cushioning are used to prevent contamination and damage.

Conclusion

Gadolinium(III) Oxide Powder (Gd₂O₃) is a versatile rare-earth material essential for high-tech industries. Its magnetic, optical, and nuclear properties make it an irreplaceable component in electronics, photonics, medical, and energy applications.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.