Introduction

The Germanium Telluride (GeTe4) Sputtering Target is a high-performance semiconductor material widely used in thin film deposition, particularly for phase-change memory (PCM) devices and thermoelectric applications. As a compound of germanium (Ge) and tellurium (Te), GeTe exhibits unique electrical and optical properties that make it ideal for data storage, infrared optics, and advanced material research.

Detailed Description

Germanium telluride is a narrow-bandgap semiconductor and a key member of the chalcogenide family. It undergoes rapid and reversible transitions between amorphous and crystalline states, enabling its use in non-volatile memory and optical switching devices.

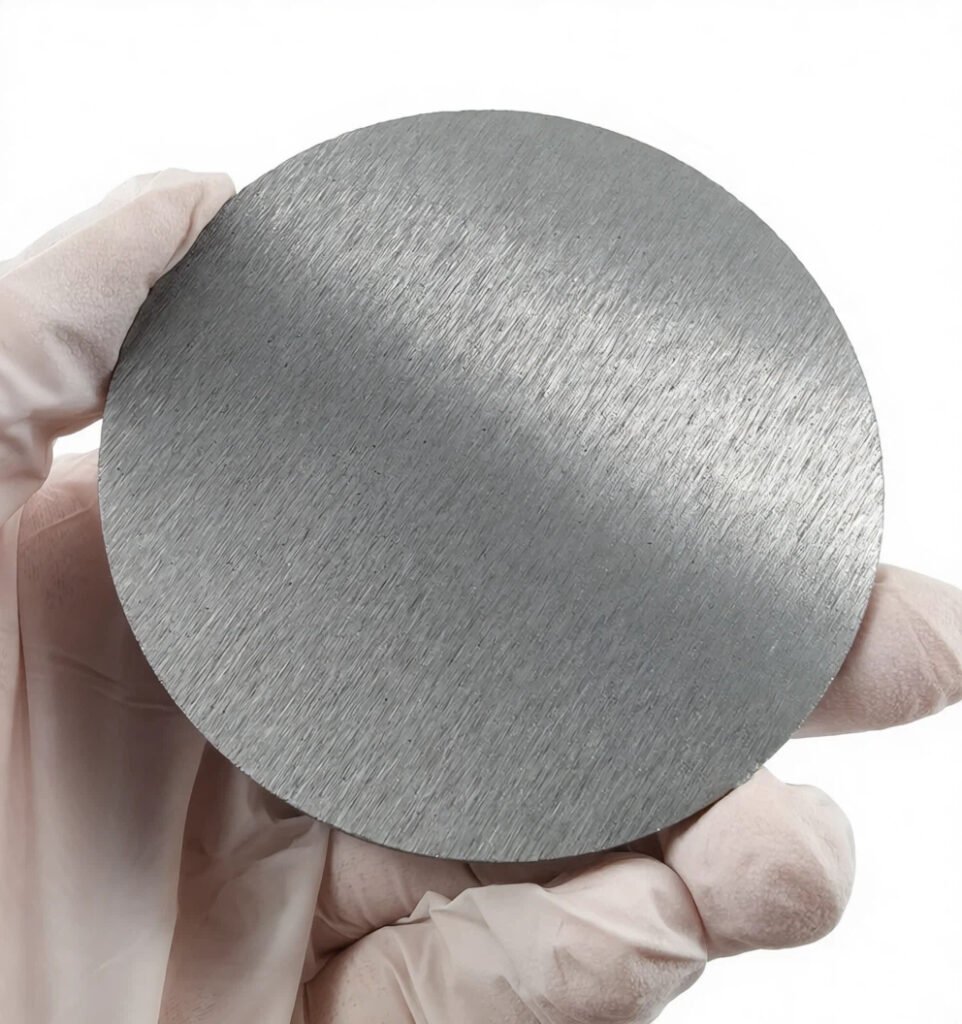

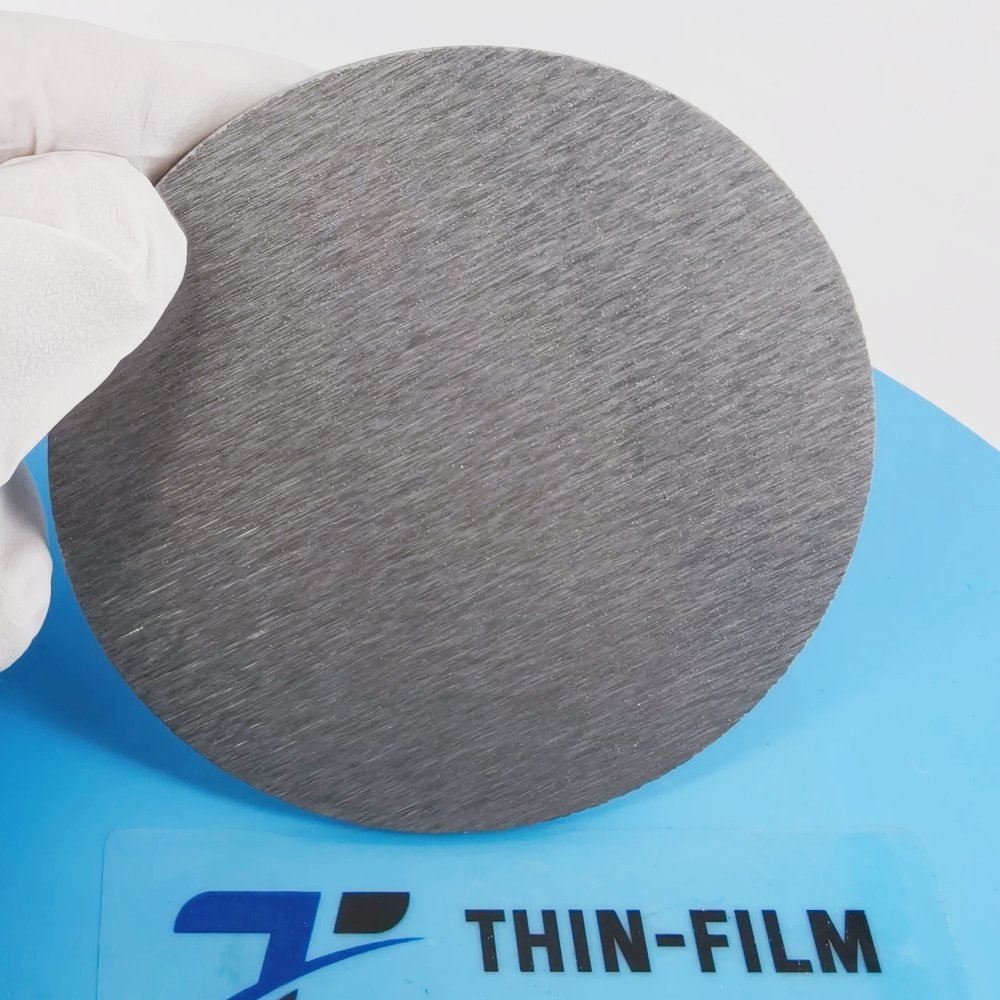

The GeTe4 sputtering target is typically fabricated by hot pressing or vacuum sintering to ensure high density and homogeneity. These characteristics provide smooth deposition behavior, stable sputtering rates, and uniform film thickness with minimal particle generation.

Key Features:

Phase-change capability – fast and stable transition between amorphous and crystalline states.

High purity and density – ensures defect-free thin films and consistent resistivity.

Good thermal and electrical conductivity.

Customizable compositions (e.g., doped GeTe) for enhanced film properties.

Applications

Germanium Telluride sputtering targets are widely used in:

Phase-change memory (PCM) – rewritable non-volatile data storage.

Optical recording media – Blu-ray and DVD re-writable discs.

Thermoelectric devices – thin films for energy harvesting and cooling.

Infrared optical coatings – due to high refractive index and IR transparency.

Research and development – chalcogenide materials and novel phase-change technologies.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Chemical Formula | GeTe4 | Defines compound stoichiometry |

| Purity | 99.9% – 99.999% | Higher purity improves film reliability |

| Density | ≥ 6.1 g/cm³ | Ensures high sputtering efficiency |

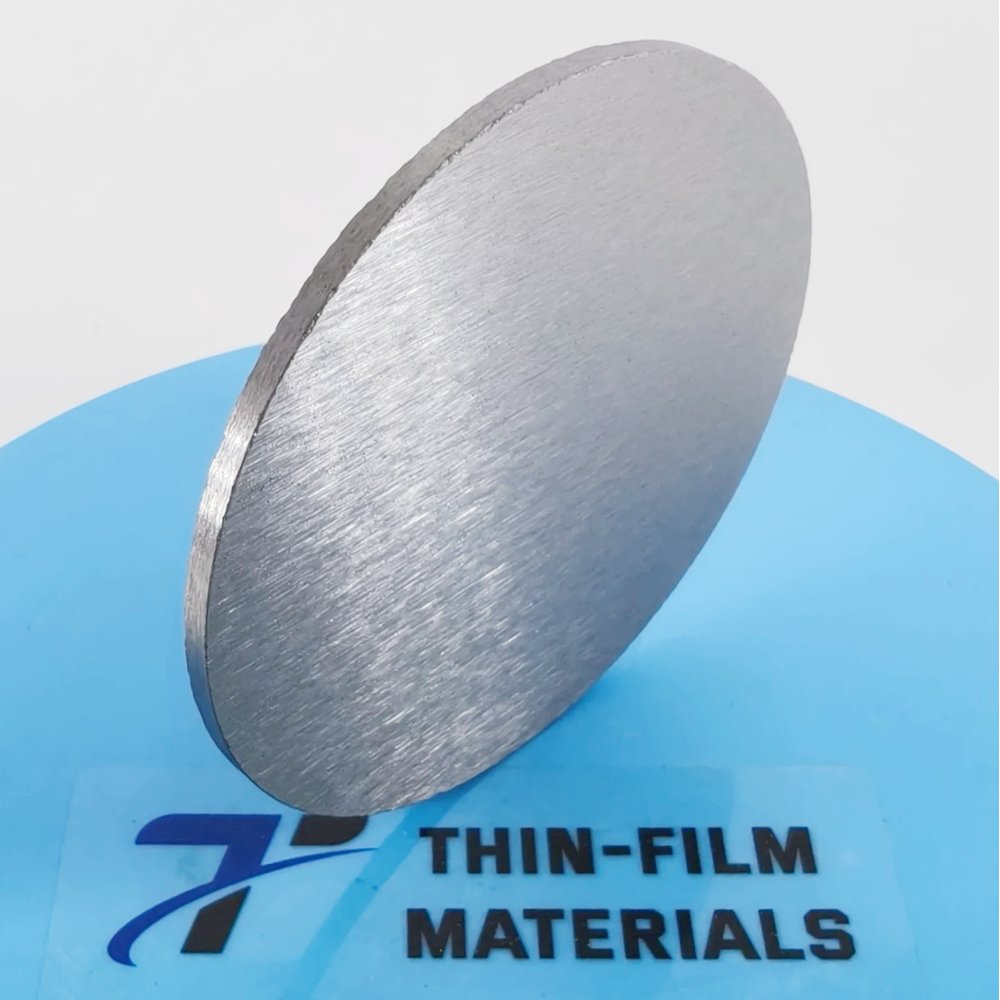

| Diameter | 25 – 300 mm (custom) | Compatible with different sputtering systems |

| Thickness | 3 – 10 mm | Balances film uniformity and target lifespan |

| Backing Plate | Copper / Molybdenum | Enhances heat dissipation and bonding strength |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Germanium Telluride (GeTe4) | Phase-change and thermoelectric use | PCM & IR coatings |

| Ge₂Sb₂Te₅ (GST) | Multi-level phase-change material | Data storage devices |

| Antimony Telluride (Sb₂Te₃) | High thermoelectric efficiency | Energy conversion films |

| Bismuth Telluride (Bi₂Te₃) | Excellent n-type thermoelectric material | Cooling devices |

FAQ

| Question | Answer |

|---|---|

| Can GeTe4 targets be customized? | Yes, composition, size, and purity can be tailored. |

| Is it suitable for RF or DC sputtering? | It can be used for both RF and DC magnetron sputtering. |

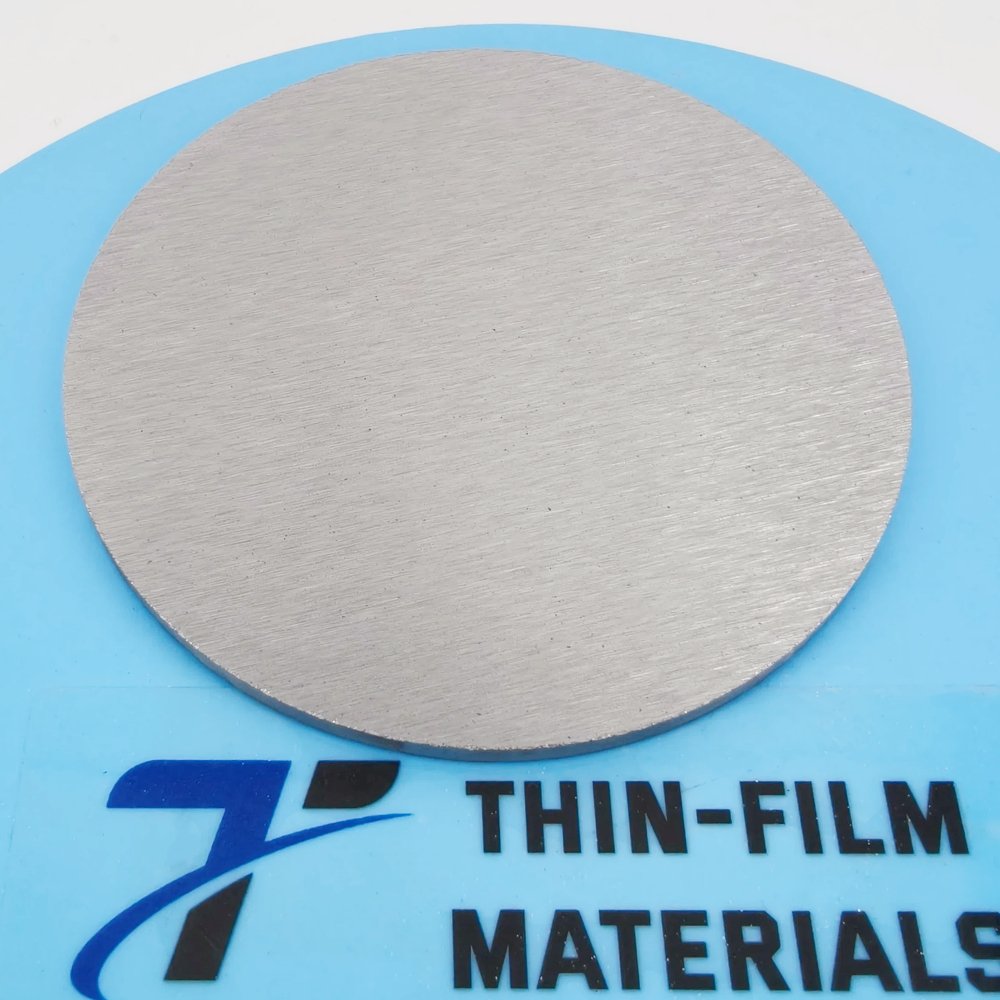

| What is the typical film color? | Films range from metallic gray to dark depending on thickness and structure. |

| How is it packaged? | Vacuum-sealed, foam-protected, and shipped in export-safe cartons. |

| Which industries use it most? | Semiconductor, optical storage, and thermoelectric energy industries. |

Packaging

Each Germanium Telluride Sputtering Target is vacuum-sealed in moisture-proof packaging with desiccants and cushioned with protective foam. Export-grade cartons or wooden crates ensure safe delivery worldwide.

Conclusion

Germanium Telluride sputtering targets offer an exceptional balance of electrical conductivity, phase-change capability, and optical performance. These properties make GeTe an essential material for next-generation memory, infrared optics, and thermoelectric devices.

For detailed specifications and quotations, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.