Superior Germanium Wafer Technology: TFM’s Commitment

TFM provides high-purity Germanium (Ge) wafers, known for their excellent carrier mobility, direct bandgap properties, and superior infrared transparency. These wafers are widely used in semiconductor, photonics, and infrared (IR) optical applications, making them ideal for high-performance transistors, solar cells, and thermal imaging systems.

Germanium wafers offer low lattice mismatch with III-V materials, facilitating high-quality epitaxial growth for advanced optoelectronic devices. Their high refractive index and infrared transmission make them a preferred choice for IR optics and sensing technologies. Additionally, Ge wafers are commonly used in heterojunction bipolar transistors (HBTs) and CMOS-compatible semiconductor devices.

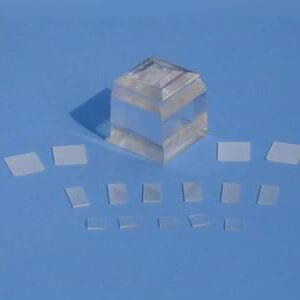

TFM supplies customized Germanium wafers in various sizes, doping types, and specifications to meet the demanding needs of research and industrial applications, ensuring exceptional material quality and performance.

Germanium Wafer Specifications

- Size: 10×3, 10×5, 10×10, 15×15, 20×15, 20×20, Dia 1”, Dia 2”, Dia 4″, Dia 6″

- Thickness: 0.33mm, 0.43mm, 0.5mm, 1.0mm

- Polished: SSP or DSP

- Orientation: <100>, <110>, <111>

- Redirection Precision: ±0.5°

- Ra: ≤5Å (5µm × 5µm)

Germanium Wafer Physical Properties

- Material: Germanium

- Growth Method: CZ

- Structure: M3

- Lattice (A): a=5.65754

- Melting Point: 937.4℃

- Density: 5.323 g/cm³

- Doped Material: Undoped, Sb-doped, In/Ga-doped

- Type: /, N, P

- Resistivity: >35 Ωcm, 0.05 Ωcm, 0.05~0.1 Ωcm

- Thermal Expansion: <4 x 10³/cm²

Reviews

There are no reviews yet.