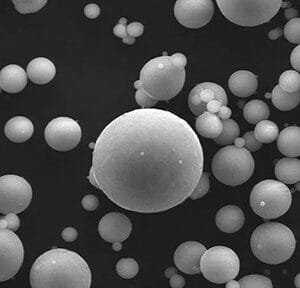

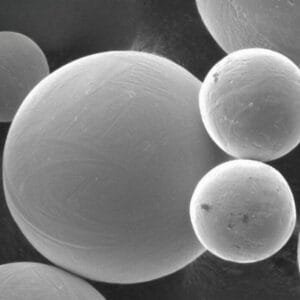

Hafnium Powder

Hafnium is renowned for its strong neutron-capturing capabilities, which makes it crucial for the manufacturing of control rods in nuclear reactors. This material is integral to regulating nuclear reactions, with the nuclear industry accounting for approximately half of the global hafnium production each year.

Hafnium Powder Application

Chemical Composition of Hafnium Powder

| Grade | Size | Chemical Composition (%) | |||||

| Hf | -60mesh -100mesh -200mesh -400mesh Other size | Hf | Zr | Al | Cr | Mg | Ni |

|---|---|---|---|---|---|---|---|

| Bal. | 0.05 | 0.0005 | 0.0001 | 0.0005 | 0.0004 | ||

| Pb | C | Cd | Sn | Ti | Fe | ||

| 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0130 | ||

| Cl | Si | Mn | Co | Mo | Sb | ||

| 0.0001 | 0.0100 | 0.0010 | 0.0001 | 0.0001 | 0.0001 | ||

| Cu | Bi | H | O | N | C | ||

| 0.0010 | 0.0001 | 0.0200 | 0.1000 | 0.0050 | 0.0050 | ||

| Grade | Chemical Composition (%) | ||||||

| Hf | Zr | H | O | N | C | Fe | |

|---|---|---|---|---|---|---|---|

| ≥ | ≤ | ||||||

| Hf-01 | 99.5 | 3.0 | 0.005 | 0.120 | 0.005 | 0.010 | 0.050 |

| Hf-1 | – | – | 0.005 | 0.130 | 0.015 | 0.025 | 0.075 |

| Sieve mesh | -60mesh, -100mesh, -200mesh, -400mesh and other size | ||||||

| Special requirements to be agreed upon by the supplier and buyer | |||||||

Reviews

There are no reviews yet.