Hafnium(IV) Oxide Powder (HfO₂)

Introduction

Hafnium(IV) Oxide Powder (HfO₂), also known as hafnia, is a high-performance ceramic material valued for its excellent dielectric properties, high refractive index, and outstanding thermal and chemical stability. It is widely used in electronics, optics, and protective coatings, especially in advanced microelectronics where silicon-based devices require next-generation insulating layers.

Detailed Description

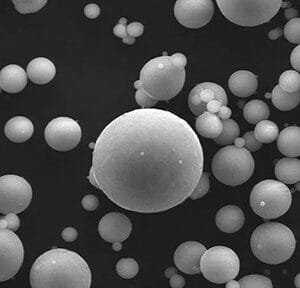

Hafnium(IV) Oxide is a white crystalline powder with a high melting point (~2,750 °C) and density of ~9.68 g/cm³. Available in purities from 99.9% (3N) to 99.999% (5N), HfO₂ is produced through high-purity refining processes to minimize metallic and non-metallic impurities.

Key features include:

High dielectric constant (k ≈ 20–25), making it an excellent replacement for SiO₂ in advanced semiconductor devices.

High refractive index (~2.0 at 550 nm), making it suitable for optical coatings and photonic devices.

Exceptional thermal stability, suitable for use in harsh environments.

Chemical inertness, providing resistance against acids and alkalis.

Strong hardness and wear resistance, enabling use in protective and structural ceramics.

Applications

Hafnium(IV) Oxide Powder is applied in:

Microelectronics: As a high-k dielectric material in MOSFETs and advanced memory devices.

Optics: Used in anti-reflective and high-refractive-index coatings.

Thermal barrier coatings: Protecting turbine blades and aerospace components.

Ceramics: Additive in advanced ceramic composites for strength and stability.

Nuclear industry: Control materials due to hafnium’s strong neutron absorption properties.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Ensures high performance in electronics/optics |

| Particle Size | 50 nm – 5 µm | Nano-grade improves thin-film applications |

| Appearance | White crystalline powder | Indicates purity and stability |

| Melting Point | ~2,750 °C | Excellent thermal stability |

| Density | ~9.68 g/cm³ | Higher density than ZrO₂, enhancing durability |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Hafnium Oxide (HfO₂) | High-k dielectric, high stability | Microelectronics, coatings |

| Zirconium Oxide (ZrO₂) | Toughness and thermal resistance | Structural ceramics |

| Aluminum Oxide (Al₂O₃) | Cost-effective, high hardness | Refractories, abrasives |

FAQ

| Question | Answer |

|---|---|

| Why is HfO₂ important in electronics? | It replaces SiO₂ as a gate dielectric in advanced semiconductors due to its high dielectric constant. |

| Can particle size be customized? | Yes, from nano to micron levels depending on the application. |

| Is HfO₂ stable in high temperatures? | Yes, with a melting point of ~2,750 °C, it is ideal for thermal barrier coatings. |

| How is it packaged? | Vacuum-sealed containers, with bulk orders in export-grade drums. |

| Which industries use it the most? | Semiconductor, aerospace, optics, nuclear, and advanced ceramics. |

Packaging

Hafnium(IV) Oxide Powder is sealed in moisture-proof, airtight bottles or bags to preserve purity. Bulk orders are shipped in protective drums with shock-absorbing fillers to prevent contamination or damage during transport.

Conclusion

Hafnium(IV) Oxide Powder (HfO₂) is a critical material for next-generation electronics, optics, and aerospace applications. Its high dielectric constant, stability, and versatility make it indispensable in industries where performance and reliability are paramount.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.