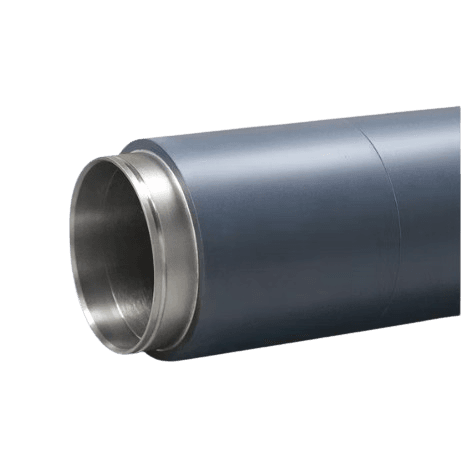

TFM offers high-quality Indium Tin Oxide rotary sputtering targets (ITO), widely used for the deposition of transparent conductive films in a variety of electronics, optoelectronics, and energy-related applications. ITO films are known for their excellent electrical conductivity, high optical transparency, and superior chemical stability, making them essential in touchscreens, flat-panel displays, solar cells, and smart windows.

The rotary sputtering target design ensures uniform and efficient deposition, promoting high-quality, consistent ITO films on large-area substrates. ITO’s high conductivity and transparency make it a critical material in applications requiring a combination of electrical performance and optical clarity, such as electrostatic dissipative coatings, conductive layers in photovoltaic devices, and optical filters.

TFM provides customized ITO rotary sputtering targets, offering precise control over material composition and purity to meet specific deposition requirements. These targets are engineered to deliver optimal results in thin-film deposition for industries such as displays, energy, and electronics, ensuring high-performance and reliable films for advanced applications.

Indium Tin Oxide rotary sputtering targets (ITO) Specifications

| Materials | Indium Tin Oxide Rotary Sputtering Target |

|---|---|

| Symbol | In₂O₃/SnO₂, ITO |

| Composition | In₂O₃/SnO₂ 90/10 wt%, In₂O₃/SnO₂ 97/3 wt% or other ratios |

| Purity | ≥99.99% |

| Theoretical Density (g/cc) | 7.14 |

| Melting Point (°C) | 1,800 |

| Production Method | Bonded Type (Cold isostatic pressing + high-temperature sintering) |

| Backing Tube | Titanium, Stainless Steel |

| Bonding Material | Indium or Elastomer |

| Size | As per customer’s drawings |

| Relative Density | ≥99% |

| Annual Capacity | 1,000 tons |

Applications

- Thin Film Photovoltaic Solar Industry

- Touch Screens

- Semiconductor Electronics Industry

- Flat Panel Display Industry

- Construction Glass Industry

TFM also offers recycling services for used ITO sputtering targets. The pricing for recycling is determined based on the remaining weight and the current market price of indium. This service supports sustainable practices and helps recover valuable materials.

For more information on ITO sputtering targets and recycling services, please contact TFM directly.

Reviews

There are no reviews yet.