Introduction

Iron Powder is a fundamental metallic material extensively used in powder metallurgy, magnetic materials, chemical processing, and advanced manufacturing. Owing to its excellent magnetic properties, good compressibility, and cost-effectiveness, iron powder remains a cornerstone material for both large-scale industrial production and research-driven applications.

Detailed Description

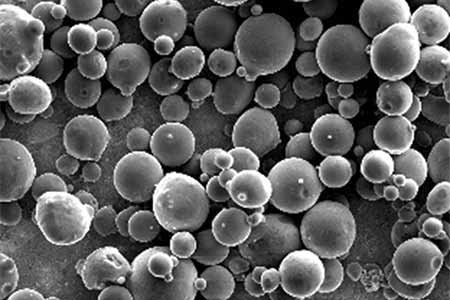

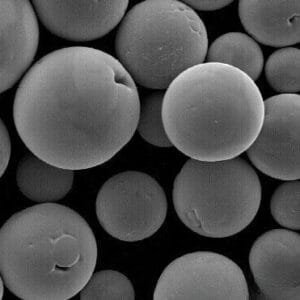

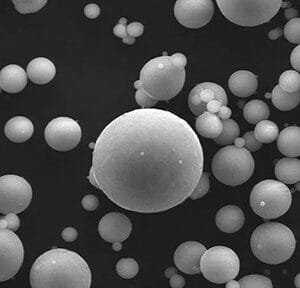

Iron powder is produced from high-quality iron through controlled reduction, atomization, or mechanical milling processes. These methods allow precise control over particle size distribution, morphology, and impurity levels, ensuring consistent performance across different applications.

Compared with bulk iron or iron ingots, iron powder offers:

High surface area, improving sintering efficiency and reaction kinetics

Excellent compressibility, ideal for powder metallurgy and pressed components

Good magnetic performance, suitable for soft magnetic and functional materials

Flexible processing, enabling blending with other powders or additives

Depending on application requirements, iron powder can be supplied with tailored particle sizes, shapes (irregular or spherical), and purity grades to optimize flowability, packing density, and final part performance.

Applications

Iron powder is widely used in:

Powder metallurgy parts and structural components

Soft magnetic materials and electromagnetic cores

Additive manufacturing and metal injection molding (MIM)

Chemical and catalytic processes

Research and development in materials science

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Material | Iron (Fe) | Provides magnetic and mechanical properties |

| Purity | 99.5% – 99.99% | Reduces impurities affecting performance |

| Particle Size | Micron to sub-micron (custom) | Influences sintering and flow behavior |

| Morphology | Irregular / Spherical (optional) | Affects packing density and processability |

| Density | ~7.87 g/cm³ (bulk) | Reference for compaction and design |

Comparison with Related Metal Powders

| Material | Key Advantage | Typical Application |

|---|---|---|

| Iron Powder | Magnetic properties, cost-effective | PM parts, magnetic cores |

| Nickel Powder | Corrosion resistance | Battery & alloy applications |

| Cobalt Powder | High-temperature strength | Superalloys, hard materials |

| Stainless Steel Powder | Corrosion resistance | Additive manufacturing |

FAQ

| Question | Answer |

|---|---|

| Can particle size be customized? | Yes, particle size distributions can be tailored upon request. |

| Is iron powder suitable for powder metallurgy? | Yes, it is one of the most widely used PM materials. |

| How is iron powder packaged? | Typically vacuum-sealed or packed under inert atmosphere. |

| Is this product suitable for laboratory research? | Yes, it is widely used in both industrial and academic research. |

Packaging

Our Iron Powder is carefully tagged and labeled to ensure traceability and quality control. It is packed in sealed, moisture-resistant containers to prevent oxidation and contamination during storage and transportation, ensuring consistent quality upon delivery.

Conclusion

Iron Powder provides a reliable and versatile solution for powder metallurgy, magnetic applications, and advanced materials research. With controlled purity, customizable particle size, and stable supply, it meets the needs of both industrial manufacturers and research institutions.

For detailed specifications and a quotation, please contact us at sales@thinfilmmaterials.com.

Reviews

There are no reviews yet.