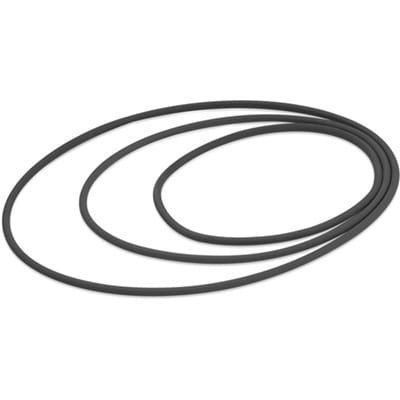

ISO HV Replacement O-Rings: Elastomeric Sealing for ISO-K and ISO-F High-Vacuum Flange Systems

ISO HV Replacement O-Rings from TFM are precision elastomeric seals specifically designed for use with ISO centering rings (not included) in high-vacuum (HV) flange connections. These o-rings ensure vacuum integrity when joining ISO-K (clamp-style) or ISO-F (bolt-style) flanges, providing the necessary compression seal between mating surfaces to support clean, leak-tight operation.

Used across a wide range of vacuum applications—from chamber ports to foreline plumbing—ISO HV Replacement O-Rings play a critical role in maintaining consistent sealing performance in systems operating down to 10⁻⁸ Torr.

Key Features of ISO HV Replacement O-Rings:

Designed for Large ISO Flanges

Compatible with all standard ISO-K and ISO-F flanges when installed in centering rings, these o-rings are essential for maintaining proper flange sealing across HV platforms.Multiple Material Options

TFM offers o-rings in several elastomer types to meet a variety of thermal and chemical requirements:Viton (Fluorocarbon FKM): Excellent chemical and high-temperature resistance, ideal for demanding vacuum environments.

Buna-N (Nitrile): Cost-effective and reliable for general-purpose HV sealing.

Silicone: Offers superior flexibility at low temperatures and cleanroom compatibility.

Vacuum Compatibility

All o-ring materials are rated for HV use with appropriate centering rings, offering sealing support for pressures from atmosphere down to ultra-high vacuum levels.Temperature Performance

Depending on material type:Viton: −20 °C to +200 °C

Buna-N: −30 °C to +120 °C

Silicone: −60 °C to +200 °C

Standard and Custom Sizes Available

TFM maintains inventory of popular ISO o-ring sizes for ISO63, ISO100, ISO160, ISO200, ISO250, ISO320, and others. Custom diameters, cross-sections, and specialty compounds (e.g., EPDM, Chemraz®, Kalrez®) are available upon request.

These ISO HV Replacement O-Rings are ideal for maintenance teams, OEM system integrators, and vacuum engineers requiring reliable, clean sealing solutions that can withstand repeated assembly cycles and exposure to vacuum-compatible lubricants or process gases.

Common Applications Include:

High-vacuum chamber maintenance

O-ring replacement in deposition and analytical systems

ISO-K/ISO-F flange resealing during system reconfiguration

Retrofit or spare parts inventory for cleanrooms or production tools

For full sealing assemblies, TFM also supplies ISO HV Centering Rings (with or without mesh screens) in aluminum, stainless steel, or hybrid constructions.

In summary, ISO HV Replacement O-Rings offer trusted sealing performance for ISO-K and ISO-F vacuum flanges. With multiple materials, size options, and compatibility with standard centering rings, they are a dependable choice for keeping vacuum systems running smoothly and leak-free.

Reviews

There are no reviews yet.