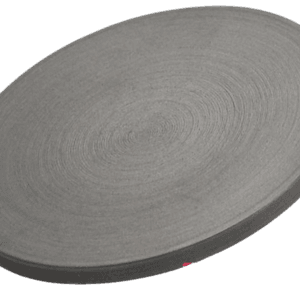

ST0441 Lanthanum Barium Manganate Sputtering Target, La(1-x)BaxMnO3

Chemical Formula: La(1-x)BaxMnO3

Catalog Number: ST0441

Purity: 99.9%, 99.99%, 99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Lanthanum Barium Manganate sputtering target come in various forms, purities, sizes, and prices. Thin Film Materials (TFM) manufactures and supplies top-quality sputtering targets at competitive prices.

Lanthanum Barium Manganate Sputtering Target Description

Lanthanum barium manganate sputtering targets consist of lanthanum, barium, manganese, and oxygen. These high-purity targets are essential in deposition processes to produce top-quality thin films. TFM focuses on manufacturing sputtering targets with purities up to 99.9995%, utilizing rigorous quality assurance procedures to ensure product reliability and performance.

Related products: Lanthanum Sputtering Target, Barium Sputtering Target, Manganese Sputtering Target

Lanthanum Barium Manganate Sputtering Target Specification

| Material Type | Lanthanum Barium Manganate |

| Symbol | La(1-x)BaxMnO3, LBM |

| Color/Appearance | Solid |

| Melting Point | N/A |

| Density | N/A |

| Type of Bond | Elastomer, Indium |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Lanthanum Barium Manganate Sputtering Target Application

The lanthanum barium manganate sputtering target is utilized in various applications, including thin film deposition, decorative coatings, semiconductors, displays, LEDs, and photovoltaic devices. It is also employed in functional coatings and various optical information storage industries, as well as for glass coating in automotive and architectural glass, and optical communication technologies.

Lanthanum Barium Manganate Sputtering Target Packing

Our lanthanum barium manganate sputtering targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care in handling these targets to prevent any damage during storage or transportation, preserving the quality of our products in their original condition.

Related Products

Related products

FAQ

What is a sputtering target?

It’s the source material (in solid form) used in sputter deposition to eject atoms or molecules that then form a thin film on a substrate.

What materials are used to make sputtering targets?

Targets can be pure metals (e.g., gold, copper, aluminum), ceramics (e.g., Al₂O₃, SiO₂, TiO₂), alloys, or composites—chosen based on the film’s desired properties.

How are sputtering targets manufactured?

They are produced by processes such as melting/casting for metals or sintering (often with hot isostatic pressing) for ceramics and composite targets to ensure high density and purity.

How does sputter deposition work with these targets?

In a vacuum chamber, a plasma (typically argon) bombards the target, ejecting atoms that travel and condense on a substrate, forming a thin film.

What factors affect the life and performance of a sputtering target?

Key factors include the target’s purity, density, grain structure, and the sputtering yield (i.e. how many atoms are ejected per incident ion), as well as operating conditions like power density and gas pressure.

How do I know when a sputtering target needs to be replaced?

Operators monitor target erosion (often by measuring the depth of the eroded “race track”) or track total energy delivered (kilowatt-hours) until it reaches a threshold that can compromise film quality.

Why do some sputtering targets need to be bonded to backing plates?

Fragile materials (such as many ceramics or certain oxides) and precious metals often require a backing plate to improve cooling, mechanical stability, and to allow thinner targets that reduce material costs.

What is the difference between DC and RF sputtering for targets?

DC sputtering is used for conductive targets, while RF sputtering is necessary for insulating targets (like many oxides) because it prevents charge buildup on the target’s surface.

How does reactive sputtering differ from standard sputtering?

In reactive sputtering, a reactive gas (e.g., oxygen or nitrogen) is introduced to form compound films on the substrate, but it may also “poison” the target surface if not carefully controlled.

Can I use customer-supplied powders to make sputtering targets?

Many manufacturers prefer to control raw material quality by sourcing their own powders; using external powders can risk impurities and inconsistent target properties.

What storage and handling procedures are recommended for sputtering targets?

Targets should be stored in clean, dry conditions (often in original packaging or re-wrapped in protective materials) and handled with gloves to avoid contamination, ensuring optimal performance during deposition.

What key parameters affect sputtering deposition rates?

Deposition rate depends on factors such as target material and composition, power density, working gas pressure, substrate distance, and the configuration of the sputtering system (e.g., magnetron design).

Reviews

There are no reviews yet.