Lithium Carbonate Sputtering Target Description

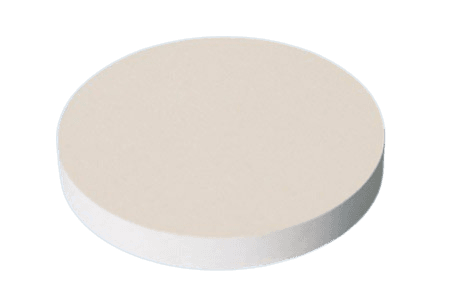

Lithium Carbonate Sputtering Target is a white sputter target with the formula Li₂CO₃. It is widely used in the processing of metal oxides.

Lithium is a chemical element derived from the Greek word ‘lithos,’ meaning stone. It was first identified in 1817 by A. Arfwedson and later isolated by W. T. Brande. The chemical symbol for lithium is ‘Li.’ It has an atomic number of 3 and is located in Period 2, Group 1 of the periodic table, belonging to the s-block. Lithium’s relative atomic mass is 6.941(2) Dalton, with the number in brackets indicating the uncertainty.

Related: Lithium Sputtering Target

Carbon is a chemical element named after the Latin word ‘carbo,’ meaning charcoal. The chemical symbol for carbon is ‘C.’ It has a hexagonal crystal structure with numerous parallel layers. In each layer, carbon atoms are arranged at the corners of regular hexagons, forming an ordered three-dimensional arrangement. Carbon exhibits excellent electrical and thermal conductivity, chemical stability, and lubricity.

Carbon is a chemical element named after the Latin word ‘carbo,’ meaning charcoal. The chemical symbol for carbon is ‘C.’ It has a hexagonal crystal structure with numerous parallel layers. In each layer, carbon atoms are arranged at the corners of regular hexagons, forming an ordered three-dimensional arrangement. Carbon exhibits excellent electrical and thermal conductivity, chemical stability, and lubricity.

Related: Carbon Sputtering Target

Lithium Carbonate Sputtering Target Specification

| Material Type | Lithium Carbonate |

| Symbol | Li2CO3 |

| Color/Appearance | White Solid |

| Molecular Weight | 73.9 |

| Density | 2.11 g/cm3 |

| Melting Point | 723 °C |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Lithium Carbonate Sputtering Target Packing

Our Lithium Carbonate Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Reviews

There are no reviews yet.