| Material Type | Lithium Nickel Manganese Cobalt Oxide |

| Symbol | LiNi0.33Mn0.33Co0.33O2 |

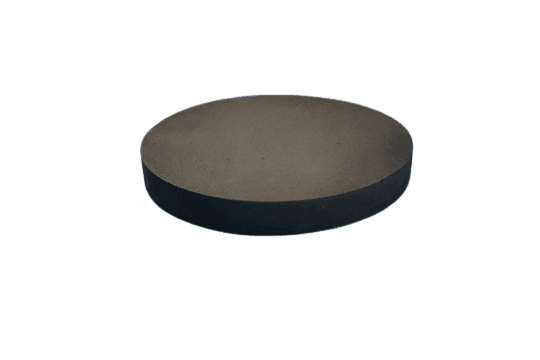

| Color/Appearance | Black, Solid |

| Melting Point (°C) | N/A |

| Theoretical Density (g/cc) | 4.80 |

| Water Solubility | Insoluble |

| Sputter | RF, RF-R, DC |

| Max Power Density* (Watts/Square Inch) | N/A |

| Type of Bond | Indium, Elastomer |

Lithium Nickel Manganese Cobalt Oxide Sputtering Targets

Overview

Lithium Nickel Manganese Cobalt Oxide sputtering targets (LiNi₀.₃₃Mn₀.₃₃Co₀.₃₃O₂), commonly known as NMC sputtering targets, are high-performance materials used in semiconductor, CVD, PVD, display, and optical applications. Their unique composition allows them to be utilized in a variety of advanced thin film deposition processes, providing high-quality coatings and films with precise control over the material properties.

Lithium Nickel Manganese Cobalt Oxide Sputtering Targets Information

- Purity: 99.9%

- Circular: Diameter ≤ 14 inch, Thickness ≤ 15 mm

- Block: Length ≤ 120 ±0.1 mm, Width ≤ 120 ±0.1 mm, Thickness ≤ 15 mm

More Information on Lithium Nickel Manganese Cobalt Oxide Sputtering Targets

Applications

- Semiconductor Manufacturing

- Chemical Vapor Deposition (CVD)

- Physical Vapor Deposition (PVD)

- Display & Optical Applications

Features

- High Density: Provides robust performance and stability in sputtering applications.

- Stoichiometric Composition: Ensures accurate film deposition with consistent properties.

- Electrically Conductive at Room Temperature: Suitable for various electrical applications and processes.

- Phase Pure: Guarantees the deposition of high-quality, phase-pure thin films.

Manufacturing Process

- In-House Powder Synthesis: High-purity metal oxide precursor materials are synthesized with high-energy mixing and particle sizing.

- Multiple Step Densification: Proprietary processes are employed for pressing and sintering to achieve optimal density and material properties.

- Cleaning & Final Packaging: Targets are cleaned to meet vacuum use standards and carefully packaged to prevent contamination during shipment.

Options Available

- 99.9% Minimum Purity: Ensures high-quality material for critical applications.

- Custom Compositions: May be available upon request to meet specific needs.

- Smaller Sizes for R&D: Available for research and development applications to support experimentation and innovation.

- Sputtering Target Bonding Service: Target bonding services are offered to enhance stability and performance.

For further information or inquiries, please reach out to us directly.

Reviews

There are no reviews yet.