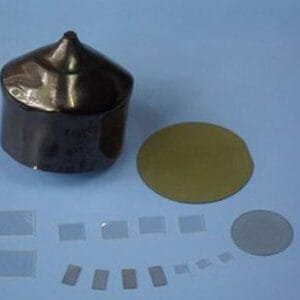

Magnesium Aluminate Substrate

The Magnesium Aluminate Substrate (MgAl₂O₄) is a versatile single-crystal material widely utilized in bulk acoustic wave and microwave devices, as well as for fast IC epitaxial substrates. Due to the challenges in maintaining a stable single-phase structure, producing high-quality MgAl₂O₄ crystals requires advanced manufacturing techniques. TFM provides superior Magnesium Aluminate (Spinel) substrates tailored to meet the demands of high-performance applications.

Physical Properties of Magnesium Aluminate (Spinel) Substrate

| Property | Specification |

|---|---|

| Material | MgAl₂O₄ |

| Structure | Cubic |

| Lattice Constant | a = 8.085 Å |

| Growth Method | Czochralski |

| Hardness | 8.0 (Mohs Scale) |

| Color | White and Transparent |

| Melting Point | 2130°C |

| Density | 3.64 g/cm³ |

| Phase Velocity | 6500 m/s at (100) shear wave |

| Propagation Loss | 6.5 dB/ms |

| Thermal Expansion | 7.45 × 10⁻⁶/°C |

Available Specifications of Magnesium Aluminate (Spinel) Substrate

TFM offers Magnesium Aluminate (Spinel) substrates in various sizes and configurations to meet specific customer requirements.

- Sizes: 10 × 5 mm, 10 × 10 mm, 20 × 20 mm, Dia 2”

- Thickness Options: 0.5 mm, 1.0 mm

- Surface Finish: SSP (Single-Side Polished) or DSP (Double-Side Polished)

- Crystal Orientations: <100>, <110>, <111>

- Redirection Precision: ±0.5°

- Edge Redirection: 2° (customizable to 1°)

- Surface Roughness (Ra): ≤ 5Å (measured over 5µm × 5µm area)

- Special Customization: Available for unique size and orientation requirements

Packaging Information

To ensure the integrity and cleanliness of the substrates, TFM packages Magnesium Aluminate (Spinel) substrates in Class 100 clean bags or wafer containers within a Class 1000 cleanroom environment.

Choose TFM for premium-quality Magnesium Aluminate (Spinel) substrates that meet the stringent demands of advanced technological applications.

Reviews

There are no reviews yet.