Description

Molybdenum Powder is a gray metallic transition metal with a Mohs hardness of 5.5, produced through methods like reducing molybdenum trioxide or ammonium molybdate. Its high purity, often exceeding 99.98%, and fine particle size of around 1-2 microns APS makes it a versatile material with unique properties. Some key characteristics include a melting point of 2,610°C, a boiling point of 5,560°C, and a density of 10.2 g/cc.

Basics of Molybdenum (Mo) Powder

- Atomic Number: 42

- Molecular Weight: 95.94 g/mol.

- Density, Theoretical: 10.29 g/cc

- Specific Heat @20°C: 061 cal/g-°C

- Melting Point: 2,610 °C

- Boiling Point: 5,560 °C

- Thermal Conductivity @100°C: 325 cal/cm2°C

- Lattice Type: Body-centered cubic

- Heat of Fusion: 70 cal/g

- Heat of Combustion: 1812 cal/g

- Crystallography: Cubic structure, body-centered

Chemical Composition of Molybdenum Powder

| Grade | FMo-1 | FMo-2 | |

|---|---|---|---|

| Mo Content (%)≥ | 99.90 | 99.50 | |

| Other Elements (%) < | Pb | 0.0005 | 0.0005 |

| Bi | 0.0005 | 0.0005 | |

| Sn | 0.0005 | 0.0005 | |

| Sb | 0.0010 | 0.0010 | |

| Cd | 0.0010 | 0.0010 | |

| Fe | 0.0050 | 0.020 | |

| Al | 0.0015 | 0.0050 | |

| Si | 0.0020 | 0.0050 | |

| Mg | 0.0020 | 0.0040 | |

| Ni | 0.0030 | 0.0050 | |

| Cu | 0.0010 | 0.0010 | |

| Ca | 0.0015 | 0.0030 | |

| P | 0.0010 | 0.0030 | |

| C | 0.0050 | 0.010 | |

| N | 0.015 | 0.020 | |

| O | 0.150 | 0.250 | |

| Special requirements to be agreed upon by the supplier and buyer | |||

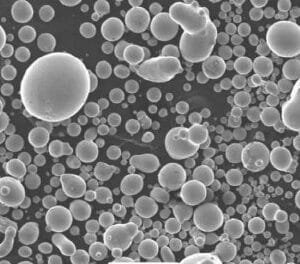

Spherical Molybdenum Powder

Our spherical Molybdenum Powder has a high level of sphericity and controlled grain size which make it the ideal powder for surface coating. It is the material of choice for many applications because it has good electrical and thermal conductivity, high melting point and high density. These properties are necessary to make it compatible with the most demanding industrial processes.

Physical Properties

| Size | 15-53 um | ||||

| Apparet density | 6.25 g/cm3 | ||||

| Tap density | 6.80 g/cm3 | ||||

| Hall flow rate | 11.00 s/50g |

Chemical Composition

| Chemical Composition – by ICP-AES | ||||||||

| Element | Mo | Pb | Bi | Sn | Sb | Cd | Fe | Al |

| Value (%) | ≥99.9 | <0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.005 | <0.001 |

| Element | Mg | Ni | Cu | Ca | Ti | Mn | Cr | W |

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.002 | <0.001 |

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

| Value (%) | 0.0032 | 0.001 | 0.01 | 0.0023 | ||||

Applications of Molybdenum Powder

- Molybdenum Powder is used in various applications, such as:

- 1.Aerospace: Molybdenum powder is used in the production of aircraft parts and military armor due to its ability to withstand extreme temperatures without significantly expanding or softening.

- 2.Electronics: Molybdenum powder is used in the production of electronic components, such as sputtering targets and X-ray anodes.

- 3.Thermal spray coatings: Molybdenum powder is used in thermal spray coatings to extend the life of products by repairing worn and damaged surfaces and protecting them from wear, corrosion, and other forms of degradation.

- 4.Additive manufacturing: Molybdenum powder is used in additive manufacturing processes, such as 3D printing and metal injection molding.

- 5.Hot isostatic pressing: Molybdenum powder is used in hot isostatic pressing applications, where it is consolidated under high pressure and temperature to form dense, high-strength components

Packaging of Molybdenum Powder

Molybdenum powder must be kept in cool dry conditions, stays unpressed. Our molybdenum powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to preserve the quality of the product in its original condition.

Reviews

There are no reviews yet.