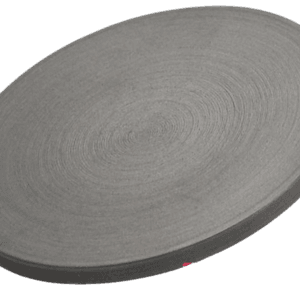

Nickel Silicide Sputtering Target Description

Nickel silicide sputtering target is a type of silicide ceramic sputtering target composed of nickel and silicon.

Nickel is a chemical element derived from the German term kupfernickel, which means “devil’s copper” or “St. Nicholas’s copper.” It was first identified in 1751 by F. Cronstedt. The element was subsequently isolated and confirmed by Cronstedt himself. Its canonical chemical symbol is Ni, and it has an atomic number of 28. Nickel is located in Period 4 and Group 10 of the periodic table, within the d-block. The relative atomic mass of nickel is 58.6934(2) Dalton, with the number in parentheses indicating the uncertainty.

Related Product: Nickel Sputtering Target

![]()

Silicon is a chemical element named after the Latin silex or silicis, which means “flint.” It was first identified in 1824 by J. Berzelius, who also accomplished its isolation. The canonical chemical symbol for silicon is Si, and it holds the atomic number 14. Silicon is positioned in Period 3 and Group 14 of the periodic table, belonging to the p-block. Its relative atomic mass is 28.0855(3) Dalton, with the number in parentheses indicating the uncertainty.

Nickel Silicide Sputtering Target Application

Nickel Silicide Sputtering Targets are utilized in a wide range of applications. They play a crucial role in thin film deposition, semiconductor production, and the creation of decorative and functional coatings. These targets are also essential in the manufacturing of displays, LEDs, and photovoltaic devices. Beyond these uses, they are important in the optical information storage industry, glass coating for automotive and architectural purposes, and optical communications. Their versatility and unique properties make them valuable across various high-tech industries.

Nickel Silicide Sputtering Target Packing

Our Nickel Silicide Sputtering Targets are carefully tagged and labeled to ensure easy identification and strict quality control. We take great precautions to protect these targets from any potential damage during storage or transportation, ensuring they reach you in perfect condition. This meticulous attention to detail guarantees that our products meet the highest standards of quality and reliability.

MSDS File

MSDS File

Reviews

There are no reviews yet.