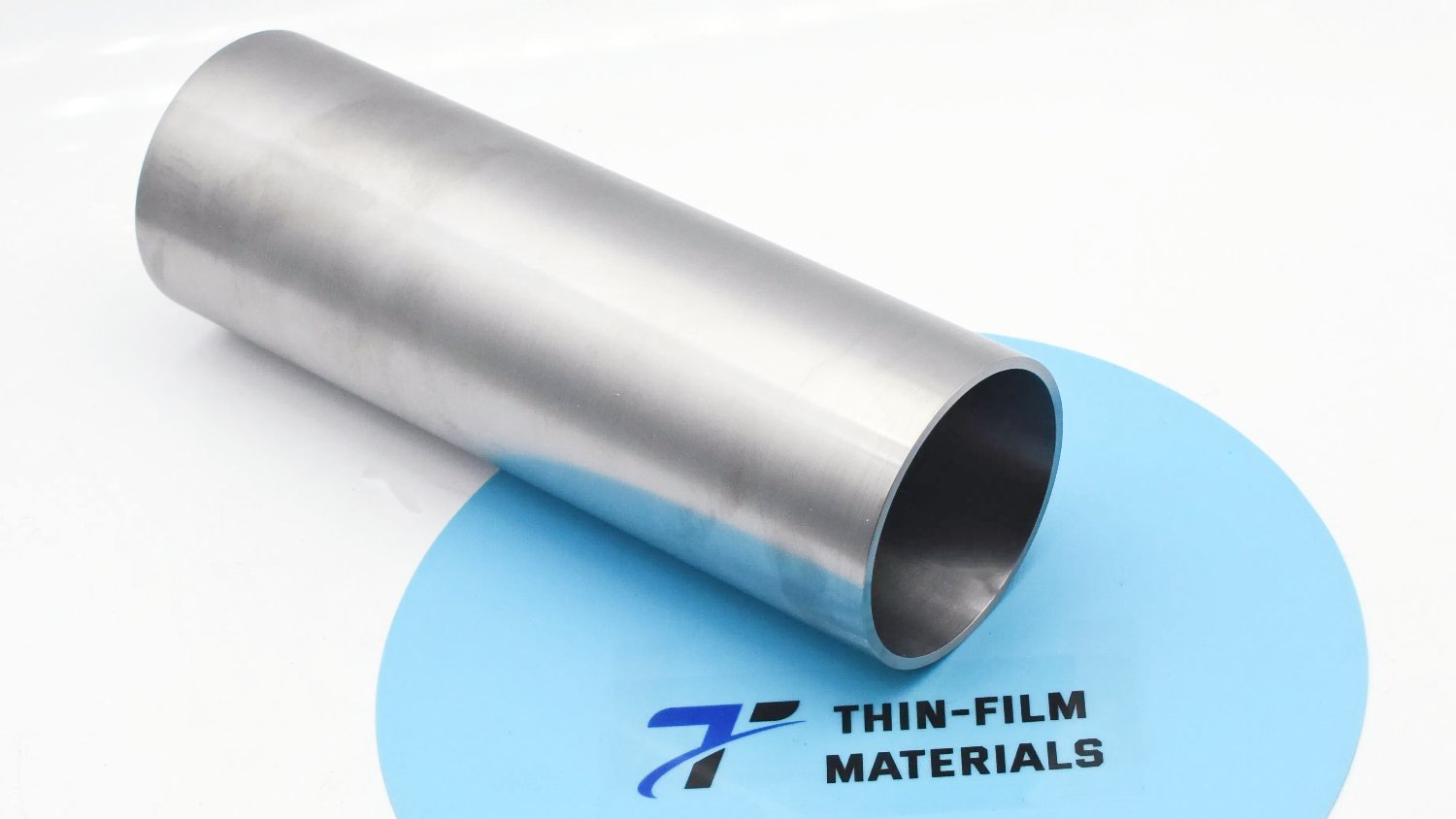

Niobium Crucible Description

Material: RO4200, RO4210

Purity: 99.95%

Customized shapes for Niobium crucibles include, but are not limited to, oval, tapered, bottomless, or round mouth.

Niobium Crucible Chemical Composition

| Chemical Composition (%) | ||||||||||||

| Material | Main elements(%) | Impurities (Maximum %) | ||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| RO4200 | Remainder | 0.004 | 0.004 | 0.002 | 0.005 | 0.005 | 0.002 | 0.07 | 0.015 | 0.0040 | 0.0015 | 0.003 |

| RO4210 | Remainder | 0.01 | 0.01 | 0.005 | 0.02 | 0.01 | 0.004 | 0.10 | 0.02 | 0.01 | 0.0015 | 0.01 |

| Material Type | Niobium |

| Symbol | Nb |

| Atomic Number | 41 |

| Color/Appearance | Gray, Metallic |

| Melting Point | 2,468 °C |

| Density | 8.57 g/cc |

Niobium Crucible Mechanical Requirements (annealed condition)

| Grade | Tensile strength δbpsi (MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ gage length, %, ≥ | |

| >=0.010 | <0.010 | |||

| RO4200, RO4210 | 18000 (125) | 12000 (85) | 25 | 20 |

Niobium Crucible Packaging

Niobium Crucible Packaging

Our high performance Niobium crucibles are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

Reviews

There are no reviews yet.