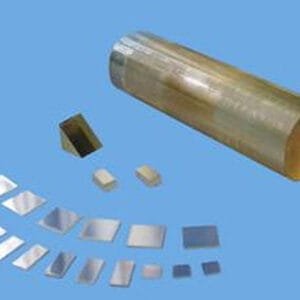

Niobium Doped Strontium Titanate Substrate

Physical Properties of Niobium Doped Strontium Titanate Substrate

| Property | Details |

|---|---|

| Material | Nb: SrTiO3 |

| Nb Concentration | 10%, 7%, 0.5%, 0.1% |

| Resistivity (Ω·cm) | 0.0035, 0.007, 0.05, 0.08 |

| Migration Rates (cm²/Vs) | 98.5, 8.5, 6.5 |

Specifications of Niobium Doped Strontium Titanate Substrate

- Size: 10×3, 10×5, 10×10, 15×15, 20×15, 20×20, Dia 15, Dia 20, Dia 1”

- Thickness: 0.5 mm, 1.0 mm

- Polished: SSP or DSP

- Orientation: <100>, <110>, <111>

- Redirection Precision: ±0.5°

- Redirection Edge: 2° (special at 1° available)

- Angle of Crystalline: Special sizes and orientations available upon request

- Surface Roughness (Ra): ≤5Å (5µm × 5µm)

Packaging of Niobium Doped Strontium Titanate Substrate

The substrates are securely packaged in class 100 clean bags or wafer containers within a class 1000 clean room environment to ensure their quality and cleanliness.

Reviews

There are no reviews yet.