Key Characteristics of Nylon Thermoplastic Powder

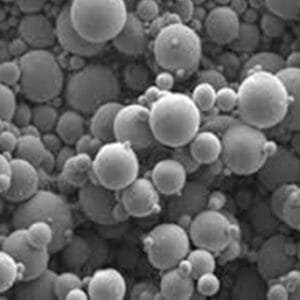

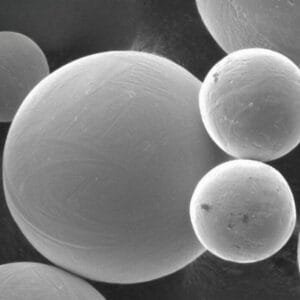

Fine Particle Size: The powder features particles smaller than 50 μm, ensuring uniform distribution.

Melting Temperature Proximity: The softening point closely aligns with the melting temperature for smoother processing.

No Wax or Grease Residue: During the molding process, no wax or grease is emitted, resulting in cleaner manufacturing.

Durable Physical Properties: Products made from a nylon matrix exhibit excellent physical strength and resilience.

Smooth Finish: Printed products have a fine texture with no roughness, offering high-quality finishes.

Thermal and Chemical Stability: The powder provides excellent stability under heat and resistance to various chemicals.

Nylon Thermoplastic Powder Specifications

Color | White |

Gloss | Mid 50 – 80 |

Finish | Smooth |

Environment | Exterior |

Industry / Application | Functional |

Chemistry | Thermoplastic Nylon |

Gloss at 60 Degrees | 70-90 |

Specific Gravity | 1.1 |

Impact Resistance (in/lb) | 160 |

Cure Schedule (Degrees F/mins) | 650F/6 min-475F/1 min |

Former Product Code | 70-7001 |

Recommended Film Thickness (mils) | 10.0-12.0 |

Applications of Nylon Thermoplastic Powder

- Rainwater gutters and downpipes

- Roof rack components

- Outdoor wirework

- Garden equipment

- Industrial roof insulation supports

- Display equipment

- Handrailing

- Security posts

- Barriers

- Roofing components for fall arrest and ventilation

- Filter screens and frames

- Vehicle underbody parts

Nylon Thermoplastic Powder Packaging

The powder is available in 2.5kg, 5kg, or 25kg packages, with custom sizes available upon request. Packaging options include plastic bottles, cans, or iron containers, depending on your requirements.

Reviews

There are no reviews yet.