Osmium Rubidium Sputtering Target Description

Osmium is a chemical element represented by the symbol **Os** and atomic number **76**. It is a hard, brittle, and bluish-white metal belonging to the platinum group. Osmium is found in trace amounts in platinum ores and is known for being the densest naturally occurring element, with a density of 22.59 g/cm³, as determined by X-ray crystallography. Due to its extreme hardness and durability, osmium is commonly used in alloys with platinum, iridium, and other platinum-group metals. These alloys are utilized in manufacturing fountain pen nibs, electrical contacts, and other components that demand high resilience. Despite its utility, osmium is among the rarest elements in the Earth’s crust.

Osmium is a chemical element represented by the symbol **Os** and atomic number **76**. It is a hard, brittle, and bluish-white metal belonging to the platinum group. Osmium is found in trace amounts in platinum ores and is known for being the densest naturally occurring element, with a density of 22.59 g/cm³, as determined by X-ray crystallography. Due to its extreme hardness and durability, osmium is commonly used in alloys with platinum, iridium, and other platinum-group metals. These alloys are utilized in manufacturing fountain pen nibs, electrical contacts, and other components that demand high resilience. Despite its utility, osmium is among the rarest elements in the Earth’s crust.

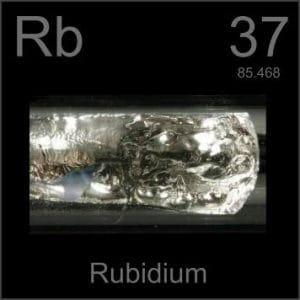

Rubidium is a chemical element with the symbol **Rb** and atomic number **37**. It is a very soft, silvery-white metal that belongs to the alkali metal group. Rubidium is similar in appearance and properties to potassium and cesium, exhibiting comparable softness and electrical conductivity. Due to its high reactivity, rubidium cannot be exposed to atmospheric oxygen and moisture; it must be stored in an inert environment to prevent it from reacting with air or water.

Rubidium is a chemical element with the symbol **Rb** and atomic number **37**. It is a very soft, silvery-white metal that belongs to the alkali metal group. Rubidium is similar in appearance and properties to potassium and cesium, exhibiting comparable softness and electrical conductivity. Due to its high reactivity, rubidium cannot be exposed to atmospheric oxygen and moisture; it must be stored in an inert environment to prevent it from reacting with air or water.

Related Products: Osmium Sputtering Target, Rubidium Sputtering Target.

Osmium Rubidium Sputtering Target Specification

| Material Type | Osmium Rubidium |

| Symbol | Os/Ru |

| Color/Appearance | Solid |

| Melting Point | / |

| Density | / |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Osmium Rubidium Sputtering Target Application

The Osmium Rubidium Sputtering Target is utilized in various applications, including:

- Thin Film Deposition: Creating precise and high-quality thin films for a range of technologies.

- Decoration: Applying decorative coatings in various industries.

- Semiconductors: Fabricating components essential for semiconductor devices.

- Displays: Enhancing the performance and durability of display technologies.

- LED and Photovoltaic Devices: Contributing to the production of LEDs and solar cells.

- Functional Coatings: Developing coatings that provide specific functional properties.

- Optical Information Storage: Used in industries focusing on optical data storage solutions.

- Glass Coatings: Employed in the automotive glass industry, architectural glass applications, and other glass coatings.

Our targets are meticulously tagged and labeled to facilitate efficient identification and maintain high-quality standards. We ensure that each product is handled with the utmost care to prevent any damage during storage or transportation.

Packing

Our Osmium Rubidium Sputtering Targets are meticulously tagged and labeled to ensure easy identification and rigorous quality control. We take every precaution to prevent any potential damage during storage and transportation, ensuring that each target reaches you in optimal condition.

Reviews

There are no reviews yet.