Platinum Silver Sputtering Target Description

Platinum is a dense, malleable, ductile, highly unreactive, precious, silver-white transition metal. The name derives from the Spanish word “platino,” meaning “little silver.” Among the six platinum group metals (Pt, Pd, Os, Ir, Rh, and Ru), platinum is the most significant. It resists corrosion, being unaffected by oxygen and water, and dissolves only in aqua regia or fused alkalis. Its most notable commercial use is as a catalytic converter in vehicles, which helps reduce harmful emissions.

Platinum is a dense, malleable, ductile, highly unreactive, precious, silver-white transition metal. The name derives from the Spanish word “platino,” meaning “little silver.” Among the six platinum group metals (Pt, Pd, Os, Ir, Rh, and Ru), platinum is the most significant. It resists corrosion, being unaffected by oxygen and water, and dissolves only in aqua regia or fused alkalis. Its most notable commercial use is as a catalytic converter in vehicles, which helps reduce harmful emissions.

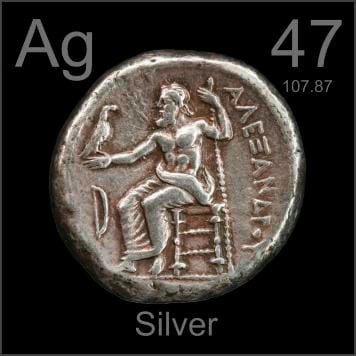

Silver is a soft, white, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. The metal is found in the Earth’s crust in the pure, free elemental form (“native silver”), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc refining. Silver sputtering target is used as decorative coatings and antibiotic coating in medical devices.

Silver is a soft, white, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. The metal is found in the Earth’s crust in the pure, free elemental form (“native silver”), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc refining. Silver sputtering target is used as decorative coatings and antibiotic coating in medical devices.

Related Products: Platinum Sputtering Target, Silver Sputtering Target.

Platinum Silver Sputtering Target Specifications

| Material Type | Platinum Silver |

| Symbol | Pt/Ag |

| Color/Appearance | Solid |

| Melting Point | / |

| Density | / |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Platinum Silver Sputtering Target Application

The Platinum Silver Sputtering Target is utilized for a range of applications including thin film deposition, decorative coatings, semiconductor fabrication, display technologies, LED and photovoltaic devices, as well as functional coatings. It is also employed in various optical information storage industries, glass coating sectors such as automotive and architectural glass, and optical communication technologies.

Platinum Silver Sputtering Target Packing

Our Platinum Silver Sputtering Targets are meticulously tagged and labeled for clear identification and stringent quality control. We take extensive measures to prevent any potential damage during storage and transportation, ensuring that the targets arrive in optimal condition.

Reviews

There are no reviews yet.