Product Overview

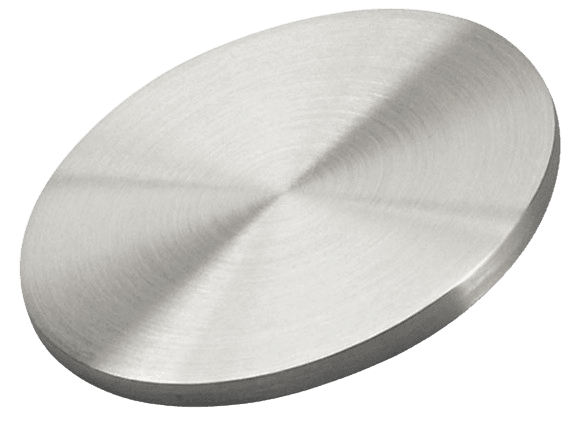

TFM offers high-quality Platinum Sputtering Targets designed for exceptional performance in various deposition processes, including semiconductor manufacturing, chemical vapor deposition (CVD), and physical vapor deposition (PVD) for display and optical devices. Known for its superior durability and outstanding catalytic properties, platinum is ideal for high-tech applications requiring high precision and reliability.

Industrial Applications of Platinum

Semiconductors: Platinum is essential for gate electrodes and barrier layers due to its excellent electrical properties.

Optical Coatings: Utilized for reflective coatings in optics, platinum is valued for its high reflectivity and stability.

Catalytic Converters: Platinum acts as an effective catalyst in automotive emission control systems, reducing harmful emissions.

Medical Devices: Due to its biocompatibility and durable nature, platinum is used in medical implants and equipment.

Energy Solutions: Platinum is critical in the production of electrodes for fuel cells and photovoltaic cells, enhancing energy conversion and efficiency.

Additional Services and Customization

Custom Sizing: We offer lutetium sputtering targets in diameters ranging from 1.0″ to 6.0″ and thicknesses between 0.125″ and 0.250″. If you need other dimensions, custom sizes are available upon request to meet your specific application requirements.

Target Bonding Services: Enhance your target’s handling and performance with our indium and elastomer bonding services.

Technical Support: Our experts are available to provide assistance and consultation to help you optimize your processes and achieve the best results.

Handling and Packaging

Every lutetium sputtering target is carefully handled and packaged to prevent damage and maintain high quality throughout delivery. Our packaging standards are specifically designed to protect the integrity and purity of the lutetium, ensuring it arrives in perfect condition.

Frequently Asked Questions (FAQs)

Q1: What makes lutetium ideal for sputtering targets?

A1: Lutetium’s high melting point, excellent conductivity, and resistance to oxidation make it highly effective for sputtering applications, ensuring durable and high-quality thin films.

Q2: Can the lutetium targets be customized for specific deposition systems?

A2: Yes, we can customize the size, thickness, and bonding of the lutetium targets to meet the specific needs of various deposition systems and applications.

Q3: How do you ensure the quality of your lutetium sputtering targets?

A3: Our lutetium targets are produced under strict quality control procedures, using high-purity lutetium to ensure minimal contamination and maximum performance in your processes.

Q4: What are the storage recommendations for lutetium targets?

A4: Lutetium targets should be stored in a cool, dry place and handled with care to avoid contamination. They are shipped in vacuum-sealed packaging to protect against environmental factors.

Q5: Are there recycling options for used lutetium targets?

A5: Yes, we offer a recycling program to help our clients reduce costs and support sustainability by reclaiming valuable materials from used targets.

MSDS File

MSDS File

Reviews

There are no reviews yet.