Potassium Chloride Substrate

Potassium Chloride (KCl) is a hygroscopic crystal renowned for its use in infrared (IR) transmission applications and Fourier Transform Infrared (FTIR) spectrophotometers. This material offers excellent optical properties that are crucial in various precision industries.

Key Features

Hygroscopic Nature – Potassium Chloride is known for absorbing moisture from the air, which requires proper storage to maintain its properties.

Low Refractive Index – With its low refractive index, KCl allows for minimal light scattering, making it ideal for high-quality optical applications.

High Damage Threshold – The high damage threshold of KCl ensures that it can withstand intense laser beams, making it particularly valuable in laser-related applications.

Transparent in Infrared – KCl is transparent to infrared light, making it an essential material in the transmission of IR wavelengths.

Applications

Infrared Transmission – Commonly used in IR transmission systems where clarity and minimal interference are essential.

FTIR Spectrophotometers – Plays a key role in FTIR spectrometers, enabling high-precision chemical analysis.

Laser Systems – KCl is used in sputter barrier windows for CO₂ lasers due to its high damage threshold and optical transparency.

Physical Properties of Potassium Chloride Substrate

| Property | Specification |

|---|---|

| Material | KCl |

| Growth Method | Crystallization Process |

| Structure | M3 |

| Lattice (A) | a = 6.291 |

| Melting Point | 770℃ |

| Density (g/cm³) | 1.98 g/cm³ |

| Wave Band | 0.20 – 27.50 µm |

| Index of Refraction | 1.49025 |

| Transmission Rate | 0.91 |

| Nf | 0.01114 |

Specifications of Potassium Chloride Substrate

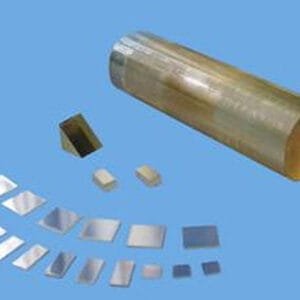

- Available Sizes:

10 mm x 10 mm, 20 mm x 20 mm, 30 mm x 30 mm, Dia 50 mm

Customized sizes are also available. - Thickness Options:

2.0 mm, 3.0 mm, 5.0 mm - Crystal Orientation:

<100>, <110>, <111> - Surface Roughness (Ra):

< 20 nm

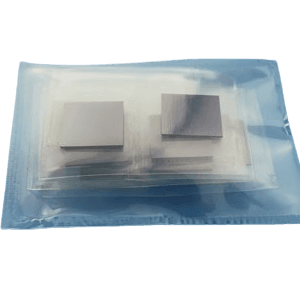

Packaging Information

Potassium Chloride substrates are packaged in a Class 100 clean bag or wafer container within a Class 1000 clean room to maintain purity and integrity.

MSDS File

MSDS File

Reviews

There are no reviews yet.