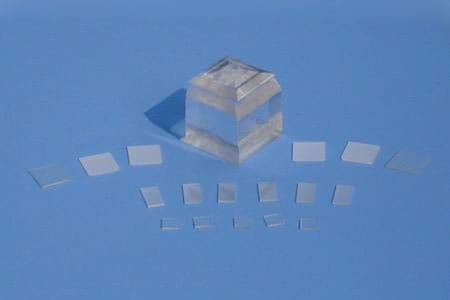

Potassium Tantalate Substrate (KTaO₃)

TFM offers high-quality Potassium Tantalate (KTaO₃) substrates, valued for their excellent dielectric properties, high permittivity, and superior crystal structure. These substrates are ideal for thin-film epitaxy, ferroelectric devices, and high-frequency applications.

KTaO₃ substrates are particularly well-suited for quantum materials, electro-optical devices, and photonic research due to their high dielectric constant and low loss tangent. Their high refractive index and transparency make them effective for use in optical coatings and photonics, especially for applications requiring precise control of light propagation. KTaO₃’s low lattice mismatch with various perovskite materials allows for high-quality epitaxial growth, making it a popular choice for ferroelectric and piezoelectric thin films, as well as high-performance capacitors and memory devices.

TFM supplies customized Potassium Tantalate substrates in various sizes and orientations to meet the demanding requirements of advanced materials research and device fabrication.

Key Physical Properties

| Property | Value |

|---|---|

| Material | KTaO₃ (Potassium Tantalate) |

| Structure | Cubic |

| Growth Method | Czochralski |

| Hardness | 6.0 (Mohns) |

| Melting Point | 1352.2℃ |

| Density | 7.025 g/cm³ |

| Refractive Index | 2.226 @ 633 nm, 2.152 @ 1539 nm |

| Thermal Expansion Coefficient | 4.027 × 10⁻⁶/K |

| Transparent Wavelength | 380 ~ 4000 nm |

Specifications

- Size: 20×20 mm, 10×10 mm, 5×5 mm

- Thickness: 0.5 mm

- Polishing: SSP or DSP

- Orientation: <100>, <110>, <111>

- Redirection Precision: ±0.5°

- Angle of Crystalline: Custom sizes and orientations available

- Surface Roughness (Ra): ≤5Å (5µm × 5µm)

Packaging Details

Potassium Tantalate substrates are carefully packaged in class 100 clean bags or wafer containers within a class 1000 clean room, ensuring the highest cleanliness standards.

Choose Potassium Tantalate Substrates (KTaO₃) from TFM for superior performance in laser, optical, and semiconductor applications.

Reviews

There are no reviews yet.