Product Overview

Specifications

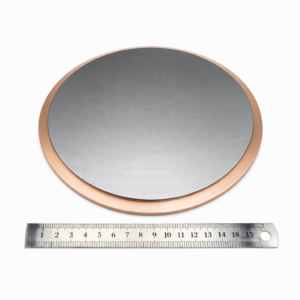

| Material Type | Ruthenium |

| Symbol | Ru |

| Color/Appearance | Gray |

| Melting Point | 2334 °C |

| Density | 12370 kg/m3 |

| Thermal Conductivity | 1.17 W·m-1·K-1 (25°C) |

| Thermal Expansion | 6.4 µm/(m·K) (25°C) |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Features and Applications of Ruthenium Sputtering Targets

High Melting Point and Density: Ruthenium targets are valued for their robustness and stability under extreme conditions, making them suitable for a variety of advanced applications.

Semiconductors and Electronics:

- Utilized for thin films in memory storage devices, microchips, and advanced circuitry.

Optical Applications:

- Employed in coatings to enhance the performance and durability of optical devices.

Chemical Industry:

- Acts as a catalyst in chemical reactions, particularly in chlorine production and hydrogen sulfide removal.

Thin Film Deposition:

- Ideal for Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) processes due to its high melting point and vapor pressure properties.

Customization and Services

Specialized bonding services for Ruthenium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

Packaging and Handling

Our ruthenium sputtering targets are meticulously handled and vacuum-sealed to ensure they are delivered in optimal condition. Typical lead times range from 2 to 5 weeks. Each package includes a Material Safety Data Sheet (MSDS) and a Certificate of Analysis (COA) for your reference.

Frequently Asked Questions

Frequently Asked Questions (FAQs)

Q1: What purity levels do you offer for Ruthenium Sputtering Targets?

A1: We provide ruthenium targets with a purity of up to 99.95%.

Q2: Can Ruthenium Targets be customized in size and shape?

A2: Yes, we offer customization in various dimensions and forms to suit specific equipment and applications.

Q3: What are the bonding options available for Ruthenium Targets?

A3: We offer indium and elastomer bonding to ensure optimal performance in your specific setup.

Q4: How is Ruthenium advantageous over other metals in sputtering processes?

A4: Ruthenium offers superior hardness, corrosion resistance, and stability at high temperatures, making it ideal for demanding deposition environments.

Q5: How do you ensure the quality of your Ruthenium Targets?

A5: Each target is rigorously tested and comes with a Certificate of Analysis (COA) to ensure high standards of quality and purity are met.

Contact Us

TFM offers Ruthenium Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.