Samarium(III) Oxide Powder (Sm₂O₃)

Introduction

Samarium(III) Oxide Powder (Sm₂O₃) is a rare-earth oxide widely used in electronics, ceramics, optics, and nuclear applications. With its distinctive pale yellow appearance and excellent chemical stability, Sm₂O₃ is a critical material for permanent magnets, catalysts, and specialty glasses.

Detailed Description

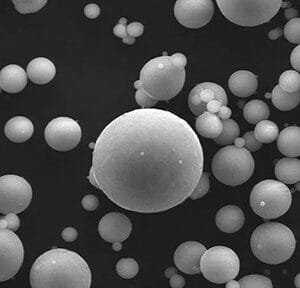

Samarium Oxide is a light yellow to pale cream-colored fine powder with a melting point of ~2,340 °C and a density of ~8.35 g/cm³. It is typically available in purities from 99.9% (3N) to 99.999% (5N), meeting both research and industrial requirements.

Key features include:

Magnetic contribution: Samarium is a key element in SmCo permanent magnets, known for high strength and thermal resistance.

Optical properties: Sm₂O₃ can be used in infrared-absorbing and UV-protective glasses.

Catalysis: Effective in chemical reactions, especially hydrogenation and dehydrogenation processes.

Stability: Insoluble in water, highly stable at high temperatures.

Applications

Samarium(III) Oxide Powder is widely applied in:

Magnet manufacturing: Raw material for SmCo permanent magnets.

Electronics: Used in thin films, capacitors, and semiconductors.

Optical glass & ceramics: Provides infrared absorption and coloration.

Catalysts: Applied in fuel cells, environmental catalysts, and organic synthesis.

Nuclear technology: Utilized as a neutron absorber in nuclear reactors.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Ensures high performance in magnets and optics |

| Particle Size | 100 nm – 5 µm | Smaller particles improve sintering and uniformity |

| Appearance | Pale yellow powder | Characteristic color of samarium oxide |

| Melting Point | ~2,340 °C | Suitable for high-temperature applications |

| Density | ~8.35 g/cm³ | Important for ceramics and magnet raw materials |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Samarium Oxide (Sm₂O₃) | Magnetic, optical, catalytic use | Magnets, catalysts, glass |

| Neodymium Oxide (Nd₂O₃) | Strong magnetic properties | NdFeB magnets |

| Europium Oxide (Eu₂O₃) | Luminescent properties | Phosphors, displays |

FAQ

| Question | Answer |

|---|---|

| What color is Sm₂O₃ powder? | Pale yellow to cream-colored. |

| Can Sm₂O₃ be used for magnets? | Yes, it is a precursor for SmCo permanent magnets. |

| Is Sm₂O₃ stable in air? | Yes, it is stable and non-hygroscopic. |

| How is it packaged? | Vacuum-sealed in moisture-proof containers, bulk shipments in lined drums. |

| Which industries use Sm₂O₃ the most? | Magnetics, optics, ceramics, catalysts, and nuclear technology. |

Packaging

Samarium(III) Oxide Powder is securely packed in vacuum-sealed bottles or bags for laboratory use. Industrial quantities are shipped in moisture-proof drums with protective lining to prevent contamination.

Conclusion

Samarium(III) Oxide Powder (Sm₂O₃) is a multifunctional rare-earth material essential in permanent magnets, optics, electronics, and nuclear applications. With its high stability, unique optical properties, and magnetic significance, it supports both cutting-edge research and industrial production.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.