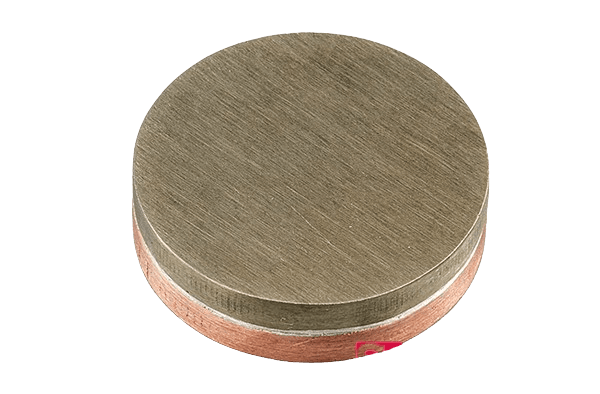

Scandium Sputtering Target Description

The scandium sputtering target retains the properties of its source material. Scandium, a transition metal with a silvery appearance, is classified as a non-lanthanide rare earth element. This versatile metal is widely used in products such as fluorescent lamps, baseball bats, and bicycle frames. In industrial applications, scandium is primarily alloyed with other metals to produce high-performance materials. The only known concentrated sources of scandium are the rare minerals thortveitite, euxenite, and gadolinite, found in Scandinavia and Madagascar.

The scandium sputtering target retains the properties of its source material. Scandium, a transition metal with a silvery appearance, is classified as a non-lanthanide rare earth element. This versatile metal is widely used in products such as fluorescent lamps, baseball bats, and bicycle frames. In industrial applications, scandium is primarily alloyed with other metals to produce high-performance materials. The only known concentrated sources of scandium are the rare minerals thortveitite, euxenite, and gadolinite, found in Scandinavia and Madagascar.

Scandium Sputtering Target Properties

| Symbol | Sc |

| Atomic Number | 21 |

| Purity | REM: 99.99% |

| Dimensions | Rotatable Scandium sputtering target: Diameter: <18”, Thickness: >0.04” Planar Scandium sputtering target: Length: <36”, Width: <12”, Thickness: >0.04” |

| Appearance | Silvery |

| Melting Point | 1541 °C |

| Boiling Point | 2830 °C |

| Density | 2985 kg/m3 |

Applications of Scandium Sputtering Target

Standard scandium sputtering materials are used in various thin film coating applications, including:

- CD-ROM production

- Decoration

- Flat panel displays

- Functional coatings

- Optical information storage

- Glass coating for automotive and architectural glass

- Optical communications

Other Uses of Scandium

- Scandium Alloys: Utilized in the production of high-performance scandium alloys.

- New Lighting Sources: Applied in advanced lighting technologies.

- Chemical Reagent: Used as a reagent for synthesizing other compounds.

- Lasers: Employed in laser applications for enhanced performance.

Scandium Sputtering Target Bonding Services

Specialized bonding services for Scandium Sputtering Targets, including indium and elastomeric bonding techniques, enhance performance and durability. Thin Film Materials (TFM) ensures high-quality solutions that meet industry standards and customer needs.

We also offer custom machining of backing plates, which is essential for sputtering target assembly. This comprehensive approach improves target design flexibility and performance in thin film deposition. Our channels provide detailed information about bonding materials, methods, and services, helping clients make informed decisions.

MSDS File

MSDS File

Reviews

There are no reviews yet.