Scandium(III) Oxide Powder (Sc₂O₃)

Introduction

Scandium(III) Oxide Powder (Sc₂O₃) is a rare, high-value ceramic material prized for its role in electronics, advanced ceramics, and high-performance lighting. With excellent optical transparency, electrical insulating properties, and high thermal stability, Sc₂O₃ supports cutting-edge applications in semiconductors, aerospace, and solid oxide fuel cells (SOFCs).

Detailed Description

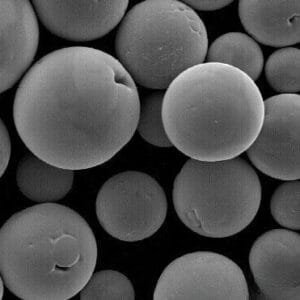

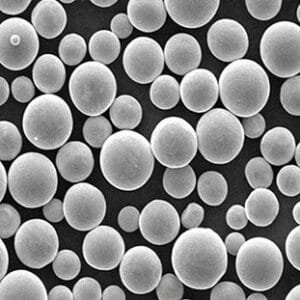

Scandium Oxide is a white, stable crystalline powder with a melting point of ~2,400 °C and a density of ~3.86 g/cm³. It is generally produced in ultra-high purities ranging from 99.9% (3N) to 99.999% (5N) to meet the demanding requirements of electronic and optical industries.

Key features include:

Optical transparency: Suitable for high-intensity lamps and advanced optical materials.

Dielectric properties: Excellent insulating behavior in electronic devices.

Thermal stability: High melting point ensures performance in extreme environments.

Catalytic activity: Useful as a promoter in catalysts for chemical reactions.

Applications

Scandium(III) Oxide Powder is widely used in:

Electronics: As a dielectric material in semiconductors and thin films.

Optics & Lighting: In scandium-halide lamps, providing bright, white light.

Ceramics: As a stabilizer for zirconia ceramics, enhancing ionic conductivity.

Aerospace & Energy: In solid oxide fuel cells (SOFCs) for higher efficiency and stability.

Research: Advanced materials studies in photonics and high-performance composites.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.999% | Critical for electronic and optical applications |

| Particle Size | 100 nm – 5 µm | Smaller particles improve sintering and uniformity |

| Appearance | White crystalline powder | Indicates high purity and stability |

| Melting Point | ~2,400 °C | Suitable for high-temperature applications |

| Density | ~3.86 g/cm³ | Important for structural and ceramic uses |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Scandium Oxide (Sc₂O₃) | High dielectric & optical stability | Semiconductors, lamps |

| Yttrium Oxide (Y₂O₃) | Optical transparency, stable | Optical ceramics, coatings |

| Zirconium Oxide (ZrO₂) | High toughness, fuel cell use | Structural ceramics, SOFCs |

FAQ

| Question | Answer |

|---|---|

| Why is Sc₂O₃ important in fuel cells? | It stabilizes zirconia electrolytes, boosting ionic conductivity and efficiency. |

| Can Sc₂O₃ be used in lighting? | Yes, scandium-halide lamps use it for bright, sunlight-like illumination. |

| Is Sc₂O₃ stable at high temperatures? | Yes, with a melting point of ~2,400 °C, it withstands extreme heat. |

| What purity levels are offered? | 3N, 4N, and 5N grades are available for different industries. |

| How is it packaged? | Vacuum-sealed bottles or bags, with bulk shipments in export-grade drums. |

Packaging

Scandium(III) Oxide Powder is securely vacuum-packed in moisture-proof containers. For larger volumes, reinforced drums or cartons are used to ensure stability during transportation and storage.

Conclusion

Scandium(III) Oxide Powder (Sc₂O₃) is an advanced rare-earth material critical to next-generation electronics, optics, ceramics, and energy technologies. Its high purity and unique properties make it indispensable in both industrial and research applications.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.