Description

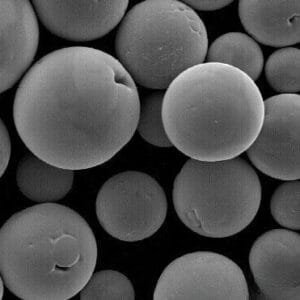

Silver, also named Argentum, is a versatile and lustrous transition metal that has played a significant role in history and continues to have a wide range of modern applications. It has a melting point of 962°C, a density of 10.5 g/cc, and a vapor pressure of 10-4 Torr at 1,105°C. Silver Powder is a highly versatile material that finds wide-ranging applications in electronics, the chemical industry, and medicine, thanks to its exceptional properties. This fine powder is highly valued for its high electrical and thermal conductivity, excellent resistance to oxidation, and germ-killing action, making it indispensable in various sectors. Advanced techniques, such as producing dendritic shape powder, are used to achieve low apparent density, enhance cost-effectiveness, and performance during its preparation. Silver powder is commonly employed in thin film coatings for semiconductor deposition, decorative purposes, and large area coatings for fuel cells. In artistic applications, pure silver powder is utilized for creating metal clay, adding silver sheen, and enabling intricate textures in art and crafts. The non-toxic nature of Silver Powder, along with its germ-killing properties, makes it a valuable component in products aimed at combating bacteria. Furthermore, silver powder is known for its stability and solubility characteristics. It can be dissolved in dilute nitric acid while maintaining a dry and fine texture like baking flour.

Silver Powder Applications

Silver Powder, available in various purities and particle sizes, serves a multitude of applications across different industries. Here are some key uses based on the search results:

- Metal Clay and Artistic Applications: Pure silver powder is utilized for making metal clay in artistic applications, adding silver sheen, fusing texture, and enabling creative possibilities in art and crafts.

- Thin Film Coating: Silver powder is used for thin film coating applications in industries like semiconductor deposition, decorative coatings, and large area coatings for fuel cells due to its high purity and quality deposition capabilities.

- Makeup and Cosmetics: Silver fine powder is employed in makeup products like embossing powders and makeup formulations to add sparkle and enhance visual effects.

- Antibacterial Properties: Silver powder has been known for its germ-killing properties, making it a valuable component in products aimed at combating germs and bacteria.

- Industrial Touch-ups: Fine silver leaf powder is used for touch-ups and detailed work in industries like frame making, where intricate detailing and ornamental finishes are required.

- Cold Cast Nickel-Silver Objects: Tin silver powder is utilized with unfilled resins to create “cold cast nickel-silver” objects, offering a cost-effective alternative for achieving metallic finishes.

Silver Powder’s versatility extends to various sectors, from art and cosmetics to industrial applications like thin film coatings and antibacterial products, showcasing its adaptability and importance across diverse industries.

Packaging

We take great care when handling our silver powders to prevent any potential damage during storage or transportation. Through this careful approach, we ensure that our products maintain their original quality and integrity throughout the entire process, which keeps them in their pristine condition for optimal performance upon their arrival.

Reviews

There are no reviews yet.