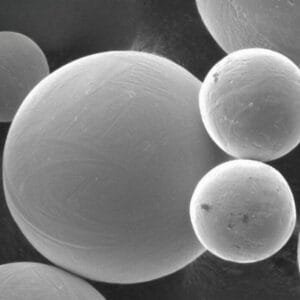

High-Quality Spherical Copper Powder Overview

Our spherical copper powder stands out for its customizable particle size, low bulk density, and superior compression and flow properties, making it ideal for 3D printing applications. The process of 3D printing with copper closely mirrors that of titanium, utilizing a method called Direct Metal Laser Sintering (DMLS). This advanced technique produces metal components that are approximately 99.99% dense, allowing them to replace traditional metal parts in a wide range of industries.

Specifications of Spherical Copper Powder

| Item | Particle Size | Purity (%) | Specific Area (m²/g) | Bulk Density (g/cm³) | Density (g/cm³) | Form | Color |

|---|---|---|---|---|---|---|---|

| ME29S -50nm | 50nm | 99.9 | 15 | 0.2 | 8.9 | Spherical | Brown |

| ME29S -300nm | 300nm | 99.9 | 4 | 1.0 | 8.9 | Spherical | Red Brown |

| ME29S -1μm | 1μm | 99.9 | 2.5 | 7.5 | 8.9 | Spherical | Red Brown |

Applications of Spherical Copper Powder

In addition to its role in 3D printing, our spherical copper powder serves a variety of other purposes, including:

- Microelectronic devices

- Conductive coatings for metallic and non-metallic surfaces

- Catalytic processes

- And more

Packaging and Handling

Each package of spherical copper powder is carefully labeled to ensure easy identification and strict quality control. We take extensive precautions to protect the product from potential damage during both storage and transportation.

Reviews

There are no reviews yet.