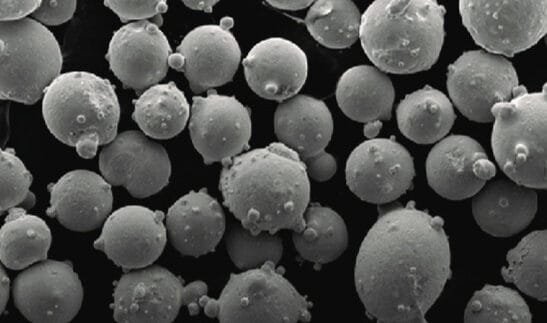

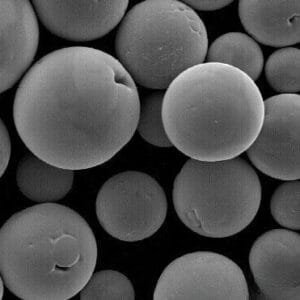

Overview of Spherical H13 Steel Powder

Spherical H13 steel powder is a high-performance material designed for manufacturing tools and components that endure significant stress and high temperatures. It is primarily used for crafting forging dies intended for large impact loads, hot extrusion dies, precision forging dies, and die-casting molds for aluminum, copper, and their alloys.

Key Properties

- Machinability & Polishing: Offers excellent machinability and polishing characteristics.

- Toughness & Plasticity: Demonstrates high toughness and plasticity.

- Wear Resistance: Exhibits superior wear resistance at elevated temperatures.

- Hardenability: Provides exceptional overall hardenability.

- Strength & Fatigue Resistance: Ensures good high-temperature strength and thermal fatigue resistance.

- Heat Treatment Stability: Minimal deformation during heat treatment and reduced iron oxide scale formation during air quenching.

Compatibility

Spherical H13 steel powder is suitable for use with various metal 3D printers, including models from:

- Renishaw

- EOS

- ConceptLaser

- SLM

- 3D Systems

- Arcam

- And other compatible systems

Specifications of Spherical H13 Steel Powder

| Property | Range |

|---|---|

| Particle Size (μm) | 0-20, 15-53, 45-105, 75-150 |

| Liquidity | ≤35s (for larger sizes), ≤25s (for smaller sizes) |

| Apparent Density (g/cm³) | 2.1 – 2.4 |

| Oxygen Content | 800-1500 ppm |

| Working Temperature (°C) | -100 to 550 |

| Tensile Strength (MPa) | 1503.1 |

| Yield Strength (MPa) | 980 ± 60 |

| Ductility (%) | 10 ± 2 |

| Liquidity | ≤18 s/50g |

Applications of Spherical H13 Steel Powder

Spherical H13 steel powder is utilized in various applications, such as:

- 3D Printing: For producing precise and durable components.

- Spacecraft: In the construction of low-temperature oxidants and fuels, as well as in spacecraft and supersonic aircraft structures.

Packaging Information

Spherical H13 steel powder is typically packaged to ensure its integrity during transportation. Options include:

- 500 g/bag: Vacuum-sealed aluminum foil bags.

- 20 kg: Metal cans.

- 100 kg or more: Steel drums or customized packaging solutions.

All packaging options are designed to be suitable for air, sea, and road transport.

Reviews

There are no reviews yet.