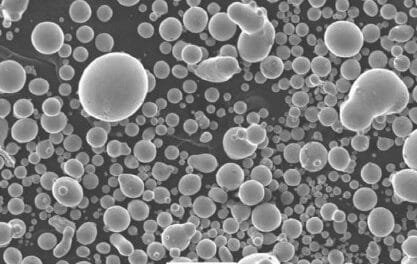

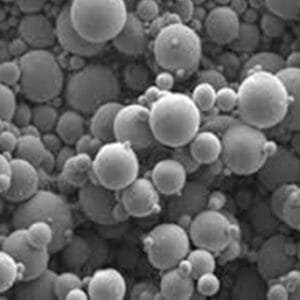

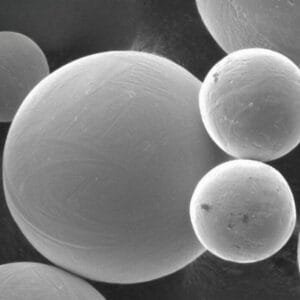

Spherical Inconel 625 Powder Description

Spherical Inconel 625 powder (UNS NO6625) is an austenitic nickel-based superalloy known for its exceptional resistance to oxidation and corrosion. It is widely used in industries such as aerospace, jet engines, and chemicals due to its ability to maintain strength and hardness at both extremely low temperatures and high temperatures, up to 1093°C. The material also offers excellent fatigue strength, making it suitable for demanding applications.

Inconel 625 is highly formable and easier to weld compared to other nickel-based alloys. Even after welding, the alloy shows strong resistance to intergranular corrosion, ensuring long-lasting performance.

Compatibility with 3D Printing Technologies

Spherical Inconel 625 powder is compatible with a wide range of metal 3D printers, including popular systems such as Renishaw, EOS, ConceptLaser, SLM, 3D Systems, Arcam, and many others, making it a versatile option for additive manufacturing applications.

Spherical Inconel 625 Powder Specification

Density | 8.44 g/cm3 |

Specific gravity | 8.44 |

Melting range | 1280°-1350 ℃ |

Shape | Spherical powder |

Particle size | 0-25,15-53,45-105,75-150μm |

Temperature | Coefficient of hardness | Elastic coefficient | |||

Fahrenheit | Centigrade | Units of 106 psi | Units Gpa | Units of 106 psi | Units Gpa |

70 | 21 | 11.4 | 79 | 29.8 | 205 |

200 | 93 | 11.2 | 77 | 29.2 | 200 |

400 | 204 | 10.8 | 75 | 28.4 | 195 |

600 | 316 | 10.5 | 72 | 27.5 | 190 |

800 | 427 | 10.1 | 70 | 26.6 | 185 |

1000 | 538 | 9.7 | 67 | 25.6 | 175 |

1200 | 649 | 9.2 | 63 | 24.4 | 170 |

1400 | 760 | 8.7 | 60 | 23.1 | 160 |

1600 | 871 | 8.2 | 57 | — | — |

Temperature | Coefficient of resistance | |

Fahrenheit | Centigrade | μΩ/cm |

70 | 21 | 128.9 |

100 | 38 | 129.6 |

200 | 93 | 131.9 |

400 | 204 | 133.9 |

600 | 316 | 134.9 |

800 | 427 | 135.9 |

1000 | 538 | 137.9 |

1200 | 649 | 137.9 |

1400 | 760 | 136.9 |

1600 | 871 | 135.9 |

1800 | 982 | 134.9 |

2000 | 1093 | 133.9 |

Spherical Inconel 625 Powder (UNS N06625) Application

Spherical Inconel 625 powder is highly versatile and finds applications across various industries due to its robust properties:

- 3D Printing Material: Ideal for additive manufacturing processes, enhancing the durability and functionality of printed parts.

- Aerospace Vehicle Components: Used in the construction of high-performance parts that withstand extreme conditions.

- Chemical Processing Equipment: Provides excellent resistance to harsh chemical environments, making it suitable for critical components in chemical processing.

- Nuclear Reactor Components: Utilized in both light and heavy water reactors due to its strength and corrosion resistance.

- Flue Gas Desulfurization Systems: Employed in components like absorption towers, reheaters, flue gas inlet baffles, fans (for moist environments), agitators, deflectors, and flues, enhancing the system’s efficiency and durability.

- Acid Gas Environments: Used in the manufacture of equipment and components exposed to acidic gases, ensuring long-term reliability.

Spherical Inconel 625 Powder (UNS N06625) Packing

Spherical Inconel 625 powders are generally packaged using high-quality materials to ensure their integrity during transportation. Here are the typical packaging options available:

- 500 grams per Bag: These powders are securely packed in vacuum-sealed aluminum foil bags, which are ideal for preserving the material’s purity and preventing contamination.

- 20 Kilograms per Metal Can: Larger quantities are packed in sturdy metal cans, providing a durable option for bulk shipping and storage.

- 100 Kilograms or More per Steel Drum: For even larger quantities, steel drums are used. Custom packaging solutions can also be arranged to meet specific requirements.

All packaging materials are designed to be suitable for various modes of transport, including air, sea, and road freight.

Reviews

There are no reviews yet.