Overview of Spherical Inconel 718 Powder

Inconel 718, a nickel-chromium-based superalloy, is renowned for its exceptional ability to perform under extreme heat and resist corrosion. Part of the Inconel alloy family, it is widely used in demanding applications, such as aerospace and high-temperature environments. This specific alloy, identified as UNS N07718, is known for its robust properties, making it a top choice in industries requiring materials with high strength and durability.

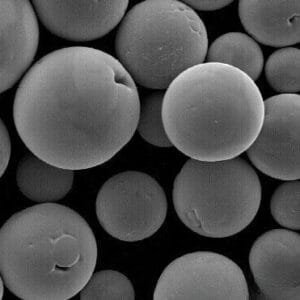

Characteristics of Spherical Inconel 718 Powder

TFM’s spherical Inconel 718 powder stands out for its superior properties, including:

- Low oxygen content

- High purity

- Excellent flowability

- High apparent and tap densities

- Near-perfect spherical shape

These qualities make it ideal for 3D printing and other advanced manufacturing techniques.

Technical Specifications of Spherical Inconel 718 Powder

| Chemical Composition(wt%) | |||||||||||||

| Inconel 718 | Fe | Ni | Nb | Mo | Cr | Al | Ti | N | Si | O | C | ||

| Balance | 52.17 | 5.24 | 3.13 | 19.02 | 0.41 | 0.89 | 0.009 | 0.06 | 0.091 | 0.022 | |||

| Physical Properties | |||||||||||||

| Apparent Density | Tap Density | Hall Flow | |||||||||||

| 4.2 g/cm3 | 4.9 g/cm3 | 18 s/50g | |||||||||||

Particle Size Distribution

- Laser Additive Manufacturing or Coatings: -15-45 µm and 25-45 µm

- Electron Beam Additive Manufacturing: -45-106 µm

- Cold Isostatic Pressing (CIP) & Hot Isostatic Pressing (HIP): -45-150 µm, 45-250 µm, and 0-250 µm

Other available superalloy options include A286 (UNS S66286), 17-7PH (AISI 631), Hiperco 27, Hiperco 50, Hastelloy C276, Invar 36, Inconel 625, and Inconel X-750.

Applications of Spherical Inconel 718 Powder

TFM’s spherical Inconel 718 powder serves a broad range of industrial applications, including:

- Additive Manufacturing (3D printing)

- Metal Injection Molding (MIM)

- Cold and Hot Isostatic Pressing (CIP and HIP)

- Surface Coatings

Packaging Options for Spherical Inconel 718 Powder

TFM offers flexible packaging solutions for spherical Inconel 718 powder to cater to various customer requirements. Packaging sizes include 2.5kg, 5kg, 25kg, or customized quantities. Containers are available in plastic or iron bottles/cans, ensuring safe handling and storage tailored to your needs.

Reviews

There are no reviews yet.