Spherical Nickel Powder Overview

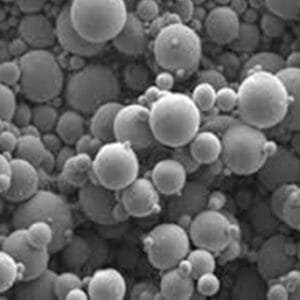

TFM’s spherical nickel powder stands out as a premium choice for advanced manufacturing applications, particularly in 3D printing. It excels in Direct Metal Laser Sintering (DMLS), a popular technique in 3D printing that creates high-density metal components with precise shapes.

Specifications of Spherical Nickel Powder

| Item | Particle Size | Purity (%) | Specific Surface Area (m²/g) | Bulk Density (g/cm³) | True Density (g/cm³) | Form | Color |

|---|---|---|---|---|---|---|---|

| ME28S-50nm | 50 nm | 100.5 | 12 | 0.74 | 8.9 | Spherical | Black |

| ME28S-500nm | 500 nm | 100.5 | 7.4 | 1.12 | 8.9 | Spherical | Black |

| ME28S-1um | 1 µm | 100.5 | 3 | 1.68 | 8.9 | Spherical | Black |

Applications of Spherical Nickel Powder

Beyond its use in 3D printing, TFM’s spherical nickel powder is versatile and finds application in various fields, including:

- Magneto fluids

- High-efficiency catalysts

- High-performance electrodes

- Efficient combustion agents

Packaging and Handling

TFM ensures that all spherical nickel powder is meticulously labeled for easy identification and quality assurance. We prioritize careful packaging to prevent damage during both storage and transportation, maintaining the integrity of the product throughout its journey.

Reviews

There are no reviews yet.