Description of Spherical TC4 Titanium-Based Powder

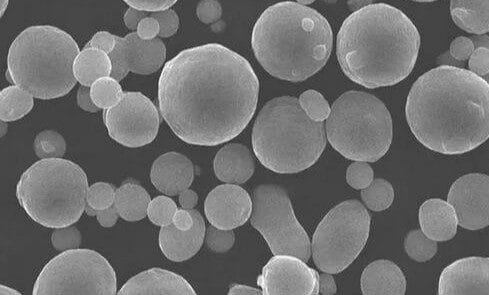

Spherical TC4 titanium-based powder, known for its composition of Ti-6Al-4V, is a prominent example of (α+β) titanium alloys. This alloy stands out due to its remarkable mechanical properties and overall performance. With its impressive corrosion resistance, TC4 titanium alloy is characterized by its low density, high specific strength, and excellent toughness and weldability. It finds extensive use across various industries including aerospace, petrochemical, shipbuilding, automotive, and pharmaceuticals.

This powder is compatible with a range of metal 3D printers such as those from Renishaw, EOS, ConceptLaser, SLM, 3D Systems, Arcam, among others.

Specifications for Spherical TC4 Titanium-Based Powder

Chemical Composition (WT %)

| Element | TC4 |

|---|---|

| Ti | Balance |

| C | <0.08% |

| Fe | <0.25% |

| N₂ | <0.05% |

| O₂ | <0.2% |

| Al | 5.5-6.76% |

| V | 3.5-4.5% |

| H₂ (sheet) | <0.015% |

| H₂ (bar) | <0.0125% |

| H₂ (billet) | <0.01% |

Product Characteristics

| Grade | Particle Size (μm) | Liquidity (s) | Apparent Density (g/cm³) | Oxygen Content (ppm) | Working Temperature (℃) | σb (MPa) | Tensile Strength (MPa) | Yield Strength (MPa) | Ductility (%) |

|---|---|---|---|---|---|---|---|---|---|

| TC4 | 0-15 | – | 2.1 | 800-1500 | -100 to 550 | ≥895 | 1080 ± 50 | 980 ± 60 | 10 ± 2 |

| TC4 | 15-53 | ≤35 | 2.2 | ||||||

| TC4 | 45-105 | ≤25 | 2.4 | ||||||

| TC4 | 75-150 | ≤25 | 2.4 |

Key Features of Spherical TC4 Titanium-Based Powder

- High purity with a spherical shape ideal for sputtering

- Consistent particle size distribution

- Optimal for thin film deposition across various industries

Applications of Spherical TC4 Titanium-Based Powder

Spherical TC4 titanium-based powder is utilized in:

- Metal 3D printing

- Aerospace compressor blades

- Shipbuilding due to its high specific strength, non-magnetic properties, and corrosion resistance

- Medical implants due to its biocompatibility

Packaging for Spherical TC4 Titanium-Based Powder

The powder is available in various packaging options:

- 500 g per vacuum-sealed aluminum foil bag

- 20 kg per metal can

- 100 kg or more per steel drum, or custom options

All packaging materials are suitable for air, sea, and road transportation.

Reviews

There are no reviews yet.