Overview of Spherical Titanium Powder

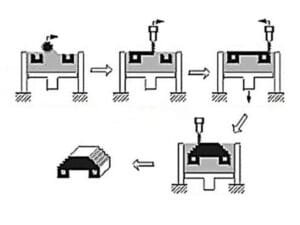

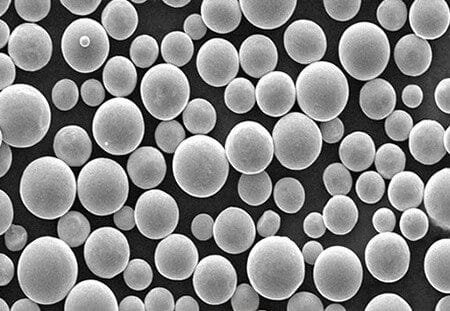

Spherical titanium powder is crucial in the realm of 3D printing, particularly in the direct metal laser sintering (DMLS) process. This advanced manufacturing technique leverages the principles of 3D printing to fabricate metal parts with precision and efficiency. By utilizing spherical titanium powder, the DMLS method enables the creation of complex and intricate titanium components that traditional manufacturing processes might struggle to achieve.

3D Printing Process with Titanium Powder

In 3D printing, titanium models are constructed using spherical titanium powder. The powder is selectively sintered by a laser to fuse the particles together, forming the final parts. Typically, a 3D printed titanium component appears matte and grayish, with a somewhat rougher surface compared to polished titanium. Despite this, 3D printing offers the advantage of producing geometries that are often beyond the reach of conventional machining techniques.

Specifications of Spherical Titanium Powder

Here’s a detailed look at the specifications for spherical titanium powder used in 3D printing:

| Grade | mainly composition (wt. %) | Impurities Max. | ||||||

| Ti | Fe | C | N | H | O | Other elements | ||

| Single | Sum | |||||||

| TA1 | balance | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | balance | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | balance | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

Packaging and Quality Control

Our spherical titanium powder for 3D printing is meticulously packaged and labeled to facilitate easy identification and maintain high-quality standards. We ensure robust protection during storage and transit to prevent any potential damage, preserving the integrity of the powder until it reaches the end user.

Reviews

There are no reviews yet.