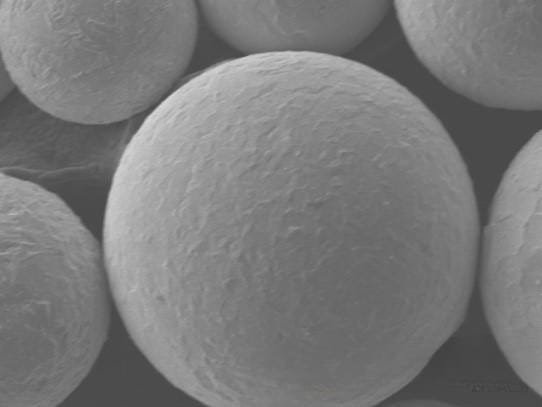

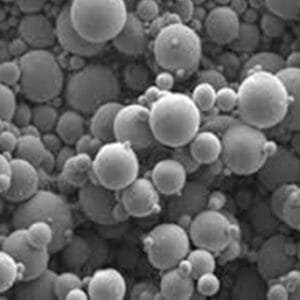

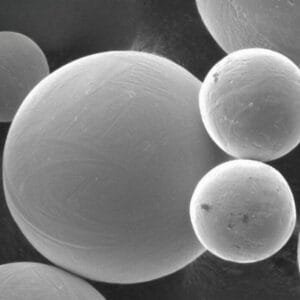

Spherical Tungsten Carbide Powder Description

Spherical Tungsten Carbide Powder Specification

CHEMICAL COMPONENT % | |||

WC | ≥99.8 | ||

Fe | <0.0300 | Sn | <0.0020 |

Si | <0.0030 | Cu | <0.0020 |

Al | <0.0020 | Na | <0.020 |

Mn | <0.0020 | Mg | <0.0020. |

Ca | <0.0020 | Ni | <0.0020 |

Bulk density | 6.5-9.5 g/cc |

Dimension of spheres | 40 – 1200 micron |

Average hardness HV0,1 | 3100 – 3800 kg/mm2 |

Peak hardness HV0,1 | 3800 – 4200 kg/mm2 |

Static strength | 20.2 kg/mm2 |

Spherical Tungsten Carbide Powder Applications

Spherical tungsten carbide powder finds extensive use across various industries due to its unique properties. Here are some of its key applications:

- Nuclear Industry: Used in components that require exceptional durability and resistance to extreme conditions.

- Automotive Industry: Employed in high-performance parts and coatings that enhance wear resistance and longevity.

- Medical Instruments: Utilized in precision tools and instruments due to its hardness and reliability.

- Metal Injection Molding: Applied in the manufacturing of complex metal parts, offering strength and precision.

- Drilling Applications: Essential in drilling tools and equipment, where its resistance to abrasion and impact is crucial.

Spherical Tungsten Carbide Powder Packing

Spherical tungsten carbide powders are typically packaged in vacuum aluminum foil bags or filled with inert gas (Ar).

-500 g/bag

-20 kg/Metal can

-100 kg and more / Steel drum, or customized

All packaging materials are suitable for air, sea and road freight.

Reviews

There are no reviews yet.