Lanthanum Calcium Manganate (LaCaMnO₃) Sputtering Target

Introduction

Lanthanum Calcium Manganate (LaCaMnO₃) Sputtering Targets are advanced ceramic oxide materials widely used in thin film research, functional coatings, and electronic device development. Known for their colossal magnetoresistance (CMR), mixed ionic–electronic conductivity, and tunable electronic phases, LaCaMnO₃ targets are a vital resource for fabricating thin films in spintronics, oxide electronics, and energy-related applications.

Detailed Description

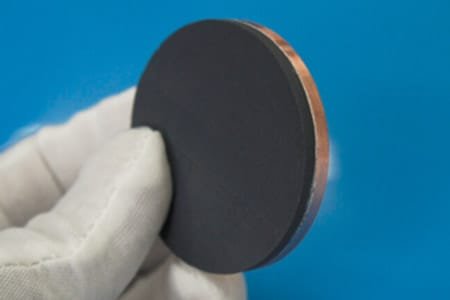

Lanthanum Calcium Manganate sputtering targets are typically produced via high-purity powder synthesis followed by hot pressing or sintering, resulting in dense, crack-free ceramic targets.

Key features include:

High Purity (≥99.9%) – ensures minimal impurities and reproducible thin film properties.

Perovskite Structure – enables phase transitions and functional electronic behavior.

Colossal Magnetoresistance (CMR) – strong change in resistance under a magnetic field, useful in spintronics.

Stable Microstructure – supports uniform sputtering rates and long service life.

Custom Options – available in different La:Ca ratios (e.g., La₀.₇Ca₀.₃MnO₃) tailored to research needs.

Applications

Lanthanum Calcium Manganate sputtering targets are widely used in:

Spintronics – thin films for magnetic sensors and memory devices.

Oxide Electronics – functional layers in complex oxide heterostructures.

Solid Oxide Fuel Cells (SOFCs) – potential electrode or interfacial material.

Thin Film Research – studies on magnetoresistance and phase transitions.

Energy & Sensor Devices – coatings for electrochemical and sensing applications.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Ensures reproducible film quality |

| Composition | La₁₋ₓCaₓMnO₃ (x = 0.2 – 0.5 typical) | Determines electronic & magnetic properties |

| Diameter | 25 – 150 mm (customizable) | Fits common sputtering systems |

| Thickness | 3 – 10 mm | Affects deposition stability |

| Bonding | Indium / Elastomer / Copper backing | Enhances thermal management |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| Lanthanum Calcium Manganate | Colossal magnetoresistance, perovskite | Spintronics, oxide thin films |

| Lanthanum Strontium Manganate (LSMO) | High conductivity, stable structure | Electrodes, ferroelectrics |

| Lanthanum Aluminate (LAO) | Excellent substrate material | Oxide heterostructures |

FAQ

| Question | Answer |

|---|---|

| Can the La:Ca ratio be customized? | Yes, different stoichiometries (e.g., La₀.₇Ca₀.₃MnO₃) are available. |

| Which industries use LaCaMnO₃ targets most? | Spintronics, advanced electronics, and R&D institutions. |

| How is the target packaged? | Each target is vacuum-sealed, foam-cushioned, and shipped in export-safe cartons or wooden crates. |

| Is bonding necessary? | For high-power sputtering, indium or elastomer bonding is recommended. |

| What deposition methods are suitable? | Primarily RF and DC magnetron sputtering. |

Packaging

Lanthanum Calcium Manganate sputtering targets are vacuum-sealed with moisture protection, individually labeled for traceability, and packaged in foam-lined export cartons or wooden crates to ensure safe delivery.

Conclusion

Lanthanum Calcium Manganate (LaCaMnO₃) Sputtering Targets are indispensable materials for cutting-edge research in spintronics, oxide electronics, and energy devices. With high purity, customizable compositions, and excellent sputtering performance, they provide researchers and industry professionals with reliable solutions for advanced thin film deposition.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.