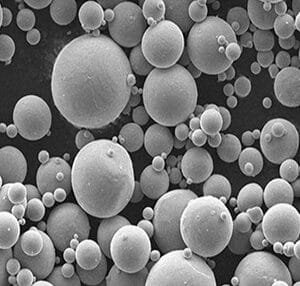

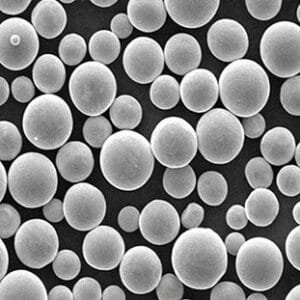

Spherical Titanium Powder

Our titanium powder and titanium-based alloy powders are known for their exceptional purity and high density, making them ideal materials for various advanced applications. These powders are crucial in metal 3D printing processes, such as laser and electron beam selective melting, and are also widely used in the production of aerospace components and biomedical titanium alloy implants, particularly for surface treatments.

Grade: TA0/Ti/Cp,TA1/Gr.1,TC4/Ti64/Gr.5,TC4 ELI,TC11/BT9,TC17,TC18,TC21,TA7,TA12,TA15/BT20,TA17,TA19/Ti6242,Ti40,Ti60,TiAl(Ti36Al,Ti48Al2Cr2Nb/Ti4822),TiNi,TiNb,ZrTi

Standard: GB/T 3620.1, GB/T 3620.2, GB/T 4698, ASTM F2924, ASTM F3001, ASTM F3187, AMS 4998, AMS 4999, GB/T 1480, GB/T 5329, GB/T 8180

Particle Size: 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm

Shape: Spherical, Ψ0≥0.90

Appearance: Gray

3D Printing Application: SLM, EBM, LMD

Other Application: PM, MIN, HIP, SP, Welding repair

Package: Vacuum packaging (aluminum foil bag) or argon-filled protective packaging (Aluminum bottle)

Pure Titanium Powder

| Particle Size Range (um) | Laser Particle Size Distribution (um) | Apparent Density (g/cm3) | Carney Flow (s/50g) | Hall Flow (s/50g) | Oxygen Content (ppm) | Nitrogen Content (ppm) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||||

| 0-15 | 6 | 15 | 21 | 2.1 | / | / | 800-1100 | ≤100 |

| 15-53 | 18 | 35 | 49 | 2.3 | ≤6 | ≤36 | ||

| 53-105 | 64 | 73 | 108 | 2.5 | ≤5 | ≤35 | ||

Titanium Alloy Powder

| Grade | Mechanical properties | ||

|---|---|---|---|

| σb(MPa) | σ0.2(MPa) | δ(%) | |

| TC4/Ti64/Gr.5 | 1040-1130 | 950-1010 | 8-18 |

| 950-1130 | 830-1080 | 9-12 | |

| ≥895 | ≥825 | ≥8-10 | |

| TC11/BT9 | 1080-1150 | 910-1030 | 6-15 |

| ≥1030 | ≥910 | ≥8 | |

| TA15/BT20 | 950-1200 | 855-970 | 8-14 |

| ≥930 | ≥855 | ≥8~10 | |

Chemical Composition Of Titanium Alloy Powder

| Grade | Chemical Composition (wt.%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Fe | Al | V | C | N | H | O | Si | Zr | Mo | Cr | |

| Commerciallly Pure Titanium | Bal. | ≤0.10 | ≤0.08 | ≤0.03 | ≤0.015 | ≤0.15 | ≤0.08 | |||||

| Ti6Al4V | Bal. | ≤0.30 | 5.50-6.75 | 3.50-4.50 | ≤0.08 | ≤0.03 | ≤0.015 | ≤0.12 | ||||

| TA15/BT20 | Bal. | ≤0.25 | 5.50-7.10 | 0.80-2.5 | ≤0.08 | ≤0.05 | ≤0.015 | ≤0.15 | ≤0.15 | 1.5-2.5 | 0.50-2.0 | |

| TC11/BT9 | Bal. | ≤0.25 | 5.80-7.00 | ≤0.08 | ≤0.05 | ≤0.01 | ≤0.15 | 0.20-0.35 | 0.80-2.00 | 2.80-3.80 | ||

| TC18 | Bal. | 0.5-1.5 | 4.4-5.7 | 4.0-5.5 | ≤0.08 | ≤0.05 | ≤0.015 | ≤0.18 | ≤0.15 | ≤0.30 | 4.0-5.5.5 | 0.5-1.5 |

TC4 Powder

| Particle Size Range (um) | Laser Particle Size Distribution (um) | Apparent Density (g/cm3) | Carney Flow (s/50g) | Hall Flow (s/50g) | Oxygen Content (ppm) | Nitrogen Content (ppm) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||||

| 0-15 | 7 | 13 | 21 | 2.1 | / | / | 800-1600 | ≤300 |

| 15-53 | 20 | 33 | 49 | 2.4 | ≤6 | ≤35 | ||

| 53-105 | 65 | 75 | 119 | 2.5 | ≤5 | ≤25 | ||

| 105-150 | 108 | 131 | 158 | 2.4 | ≤5 | ≤25 | ||

Ti2AlNb Powder Customized

| Particle Size Range (um) | Laser Particle Size Distribution (um) | Apparent Density (g/cm3) | Carney Flow (s/50g) | Hall Flow (s/50g) | Oxygen Content (ppm) | Nitrogen Content (ppm) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||||

| 15-53 | 20 | 36 | 50 | 2.5 | ≤6 | ≤60 | 800-1300 | ≤200 |

| 53-105 | 68 | 75 | 110 | 2.9 | ≤5 | ≤50 | ||

Reviews

There are no reviews yet.