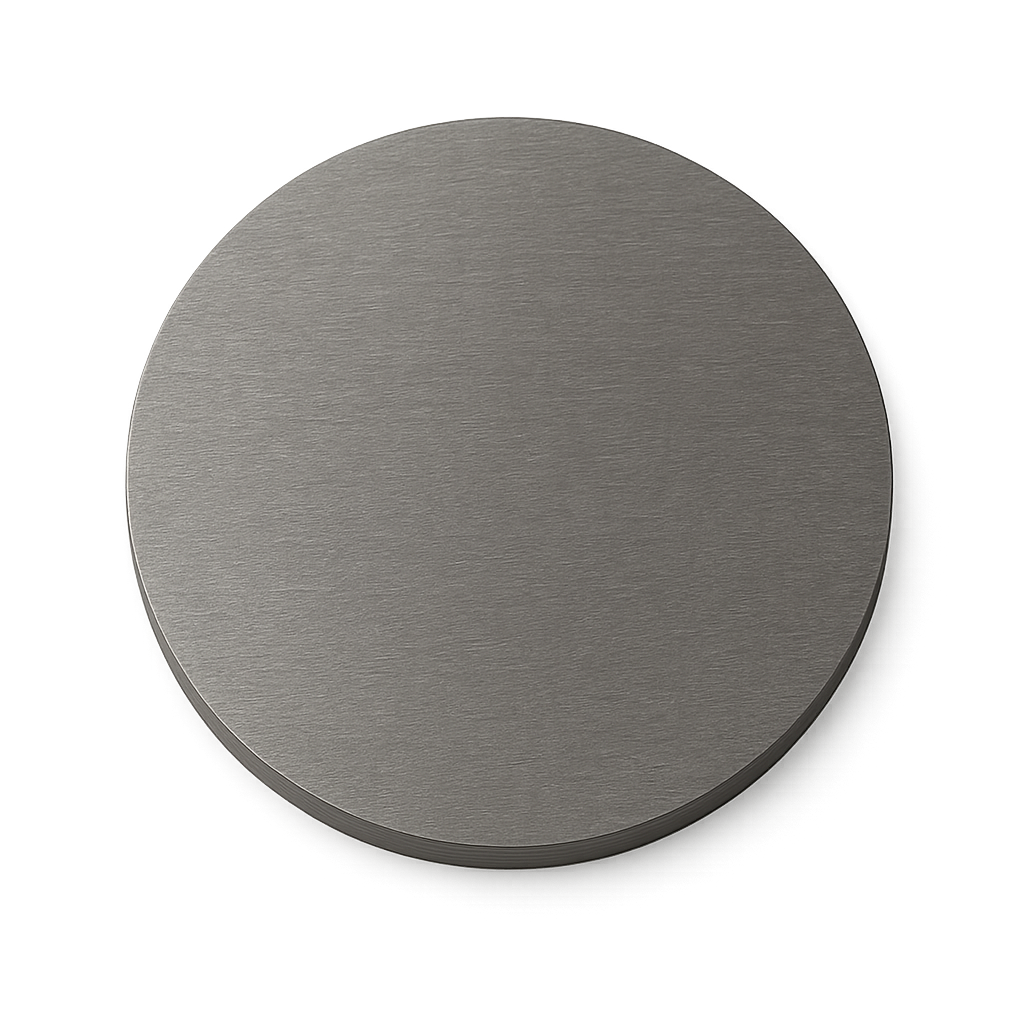

Titanium Zirconium Vanadium (TiZrV) Sputtering Target

Introduction

The Titanium Zirconium Vanadium (TiZrV) Sputtering Target is a specialized alloy material widely used in thin film deposition processes. Known for its ability to deliver high-performance coatings with excellent adhesion and stability, TiZrV targets play an essential role in vacuum technology, surface engineering, and advanced semiconductor applications. Its unique combination of three transition metals makes it a preferred choice for demanding research and industrial environments.

Detailed Description

TiZrV sputtering targets are typically manufactured in controlled alloy ratios (e.g., 1:1:1 at%), ensuring consistency and uniformity in film deposition. Each element contributes distinct properties:

Titanium (Ti): Provides excellent adhesion and corrosion resistance.

Zirconium (Zr): Enhances thermal stability and chemical resistance.

Vanadium (V): Improves mechanical strength and oxidation resistance.

The alloy is produced through powder metallurgy or vacuum melting techniques, followed by precision machining to meet tight tolerances in diameter and thickness. High-purity raw materials (up to 99.9%–99.99%) are used to minimize contamination, which is crucial for sensitive thin film applications.

Applications

TiZrV sputtering targets are employed in a wide range of industries:

Vacuum technology: Getter films for maintaining ultra-high vacuum (UHV) environments.

Semiconductors: Barrier and adhesion layers in microelectronic devices.

Optics: Thin film coatings for mirrors and precision optical components.

Surface protection: Wear-resistant and anti-corrosion coatings.

Research & Development: Functional thin films for advanced material studies.

Technical Parameters

| Parameter | Typical Value / Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Ensures low contamination in films |

| Diameter | 25 – 300 mm (custom available) | Fits different sputtering systems |

| Thickness | 3 – 6 mm | Influences sputtering rate & lifetime |

| Alloy Composition | Ti/Zr/V = 1:1:1 at% (adjustable) | Tailored film performance |

| Bonding | Indium, Copper, or Titanium backing | Improves heat dissipation & stability |

Comparison with Related Materials

| Material | Key Advantage | Typical Application |

|---|---|---|

| TiZrV | Strong getter effect, stable coatings | UHV systems, semiconductors |

| Titanium | Excellent adhesion and durability | Decorative films, microelectronics |

| Zirconium | High corrosion resistance | Nuclear & chemical industries |

| Vanadium | Oxidation resistance, strength | Specialty alloys, thin films |

FAQ

| Question | Answer |

|---|---|

| Can TiZrV targets be customized? | Yes, composition, diameter, thickness, and bonding options are fully customizable. |

| What is the main use of TiZrV in vacuum systems? | It serves as a non-evaporable getter (NEG) material, maintaining ultra-high vacuum by absorbing residual gases. |

| How are TiZrV targets packaged? | Vacuum-sealed with protective foam, then shipped in export-safe cartons or wooden crates. |

| Which industries benefit most from TiZrV targets? | Semiconductor, optics, aerospace, energy, and high-vacuum research labs. |

Packaging

All Titanium Zirconium Vanadium Sputtering Targets are carefully labeled and securely packaged. Each piece is vacuum-sealed to protect against oxidation and mechanical damage, with additional cushioning materials and export-standard crates for safe international transport.

Conclusion

The Titanium Zirconium Vanadium (TiZrV) Sputtering Target is a versatile and high-performance material that combines the best properties of titanium, zirconium, and vanadium. Its unique functionality as a getter material, coupled with excellent film quality, makes it indispensable in advanced thin film and vacuum technologies.

For detailed specifications and a quotation, please contact us at [sales@thinfilmmaterials.com].

Reviews

There are no reviews yet.