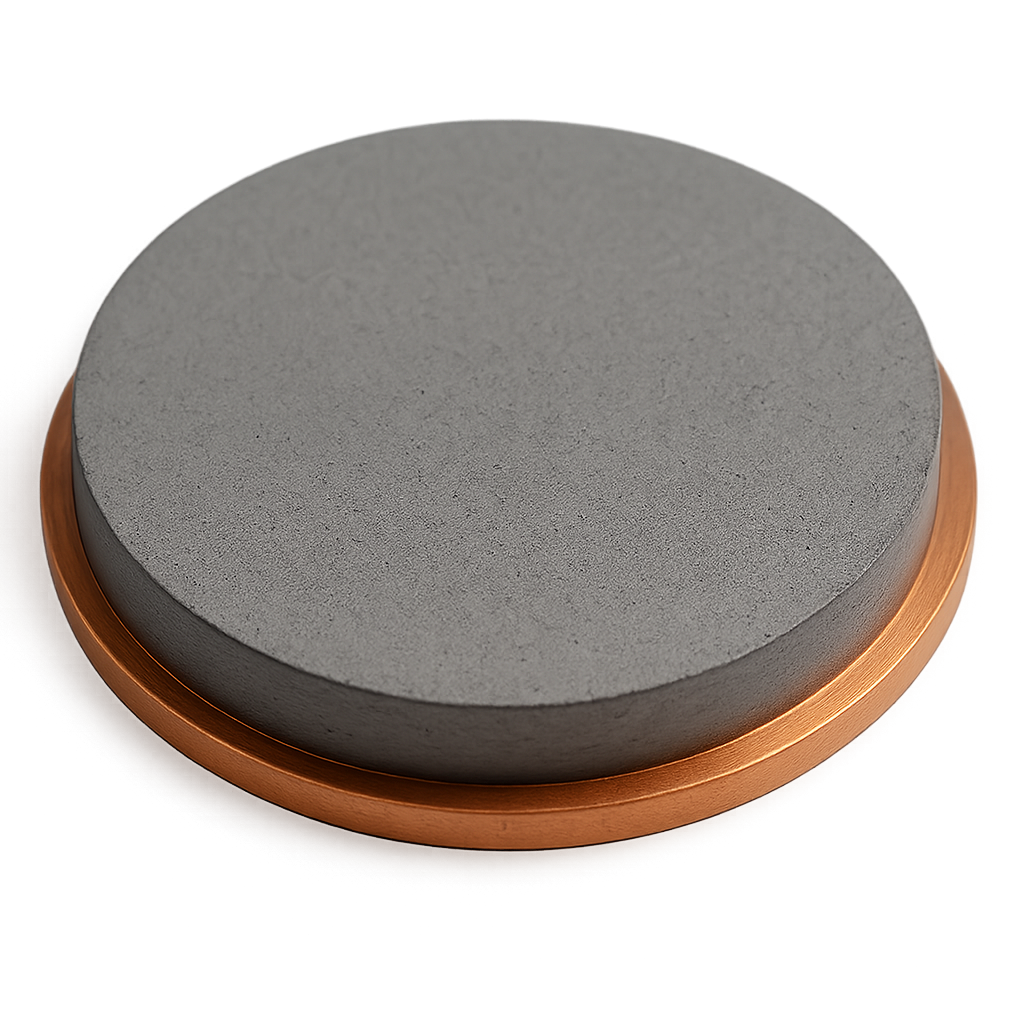

Introduction to Tungsten Aluminum Boride (WAlB₂) Sputtering Target

The Tungsten Aluminum Boride (WAlB₂) Sputtering Target is a specialized ceramic–metal composite material used for thin-film deposition. Composed of tungsten (W), aluminum (Al), and boron (B), this target combines the outstanding hardness and stability of borides with the refractory nature of tungsten and the oxidation resistance of aluminum. It is widely applied in producing durable coatings, protective layers, and multifunctional films for advanced industrial and research purposes.

Material Structure and Properties

Crystal Structure: WAlB₂ typically forms a hexagonal layered boride structure, where strong covalent B–B and metal–boron bonds ensure excellent hardness and stability.

Refractory Nature: Tungsten contributes a very high melting point (>3400 °C), thermal conductivity, and resistance to phase degradation.

Oxidation Resistance: Aluminum provides additional protection by forming stable Al₂O₃ layers at elevated temperatures.

Mechanical Strength: Boron enhances hardness, wear resistance, and structural integrity of the deposited film.

Key Features of WAlB₂ Sputtering Target

High Purity: Manufactured with purities up to 99.5–99.9%, ensuring minimal contamination in sputtered thin films.

Excellent Thermal & Chemical Stability: Stable under extreme deposition conditions and resistant to corrosion.

Versatile Sputtering: Suitable for both RF and DC magnetron sputtering systems.

Dense Microstructure: High density (>95% theoretical) targets ensure stable sputtering performance and high deposition rates.

Applications

The WAlB₂ sputtering target is employed in several cutting-edge industries where performance, stability, and durability are critical:

Protective Coatings – Thin films with high hardness and wear resistance for tools, dies, and industrial components.

Aerospace and Defense – Oxidation- and heat-resistant coatings for turbine blades, engine parts, and high-temperature components.

Electronics & Semiconductors – Barrier layers, diffusion-resistant coatings, and conductive interconnects.

Energy & Nuclear Applications – Radiation- and corrosion-resistant films suitable for extreme operating environments.

Research and Development – Multifunctional boride films with tunable mechanical, electrical, and optical properties for new materials exploration.

Fabrication & Deposition

Target Manufacturing: Typically fabricated using solid-state reaction, hot-pressing, or spark plasma sintering (SPS) to achieve high density and mechanical robustness.

Film Characteristics: Sputtered films of WAlB₂ show high hardness, oxidation resistance, and thermal stability, while maintaining good adhesion and uniformity on substrates.

Deposition Compatibility: Works well with magnetron sputtering (RF/DC) and pulsed laser deposition (PLD) systems.

Reviews

There are no reviews yet.