Vanadium Oxide Sputtering Target Description

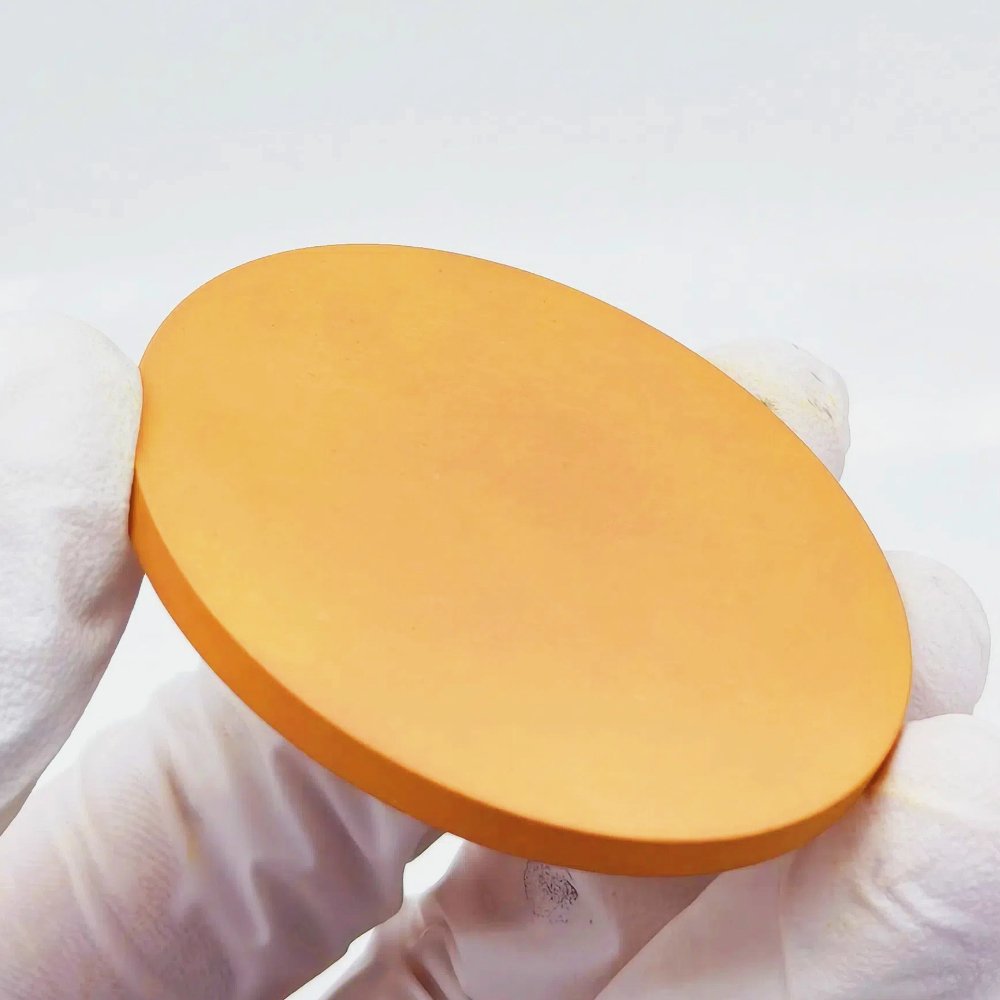

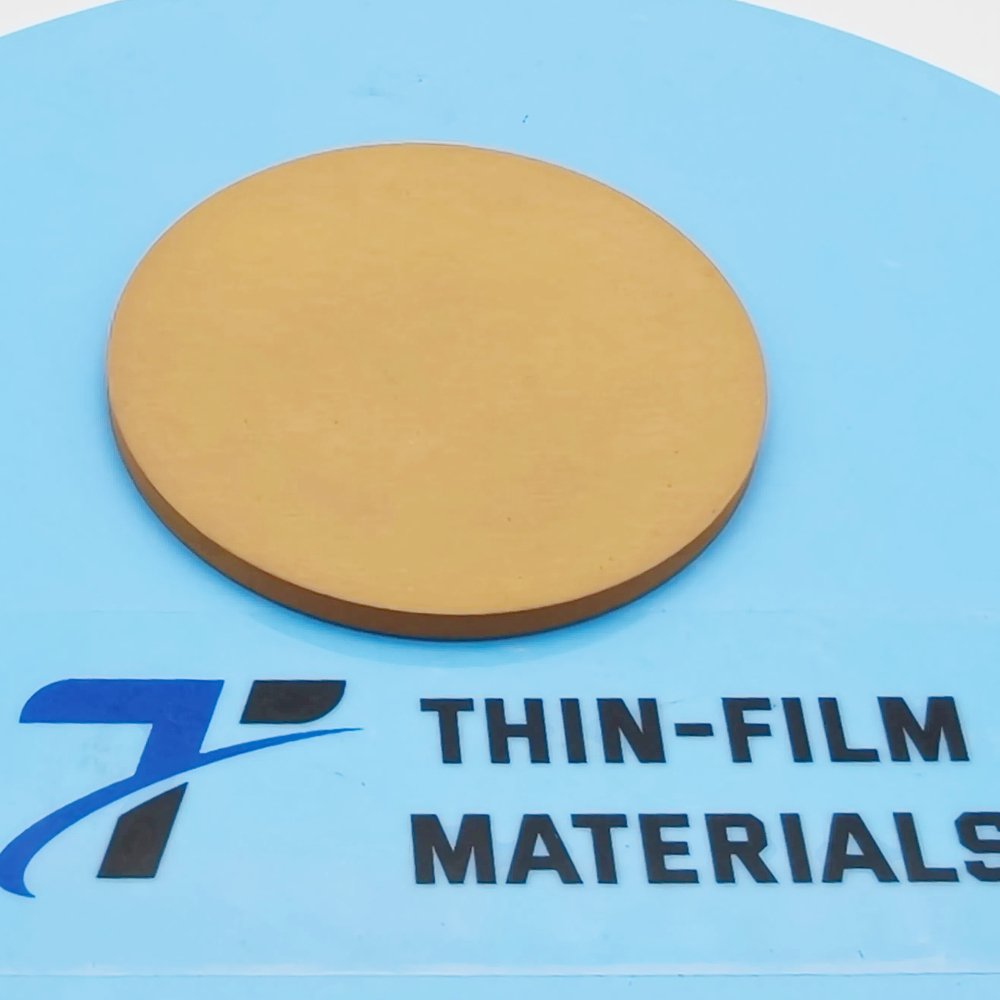

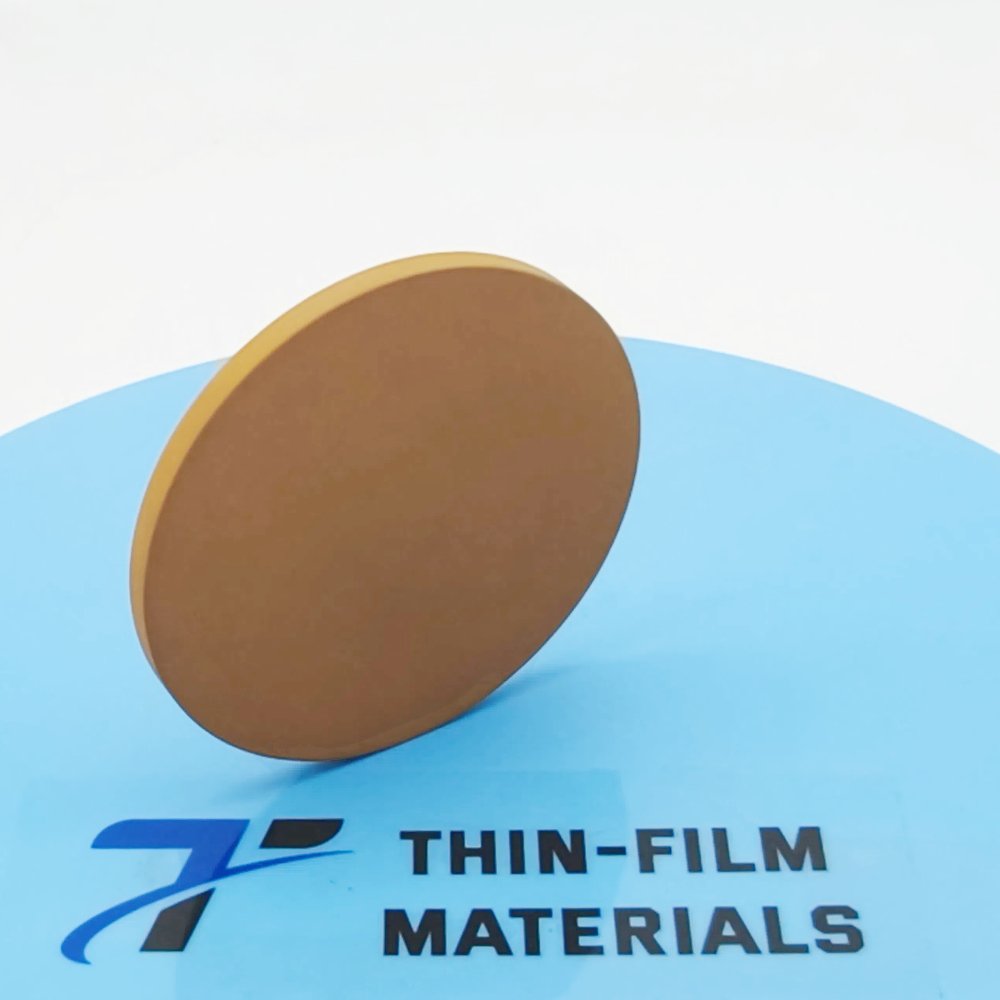

The vanadium oxide sputtering target, provided by TFM, is an oxide sputtering material with the chemical formula V₂O₅. This material is commonly used in various applications due to its properties, including its use in thin film deposition processes.

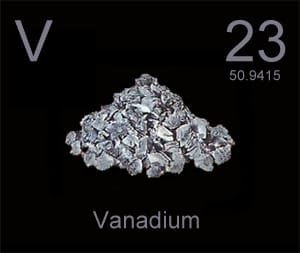

Vanadium is a chemical element named after Vanadis, an old Norse name for the Scandinavian goddess Freyja. It was first identified in 1801 by the mineralogist Andrés Manuel del Río. The isolation and further study of vanadium were later carried out by Nils Gabriel Sefström, who announced its discovery. Vanadium has the chemical symbol “V” and an atomic number of 23. It is situated in Period 4 and Group 5 of the periodic table, which places it in the d-block elements. The relative atomic mass of vanadium is 50.9415(1) Dalton, where the number in brackets indicates the measurement uncertainty.

Related Product: Vanadium Sputtering Target

Oxygen is a chemical element with the symbol “O” and atomic number 8. The name “oxygen” comes from the Greek words ‘oxy’ and ‘genes,’ meaning “acid-forming.” It was first identified by Carl Wilhelm Scheele in 1771, who observed it but did not publish his findings immediately. Joseph Priestley independently discovered oxygen and published his findings in 1774, which led to the widespread recognition of the element. Oxygen is located in Period 2, Group 16 of the periodic table, part of the p-block elements. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in parentheses indicating the uncertainty of the measurement.

Oxygen is a chemical element with the symbol “O” and atomic number 8. The name “oxygen” comes from the Greek words ‘oxy’ and ‘genes,’ meaning “acid-forming.” It was first identified by Carl Wilhelm Scheele in 1771, who observed it but did not publish his findings immediately. Joseph Priestley independently discovered oxygen and published his findings in 1774, which led to the widespread recognition of the element. Oxygen is located in Period 2, Group 16 of the periodic table, part of the p-block elements. The relative atomic mass of oxygen is 15.9994(3) Dalton, with the number in parentheses indicating the uncertainty of the measurement.

Vanadium Oxide Sputtering Target Specification

| Compound Formula | V2O5 |

|---|---|

| Molecular Weight | 181.88 |

| Appearance | Yellow to rust color |

| Melting Point | 690 °C |

| Density | 3.35 g/cm3 |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

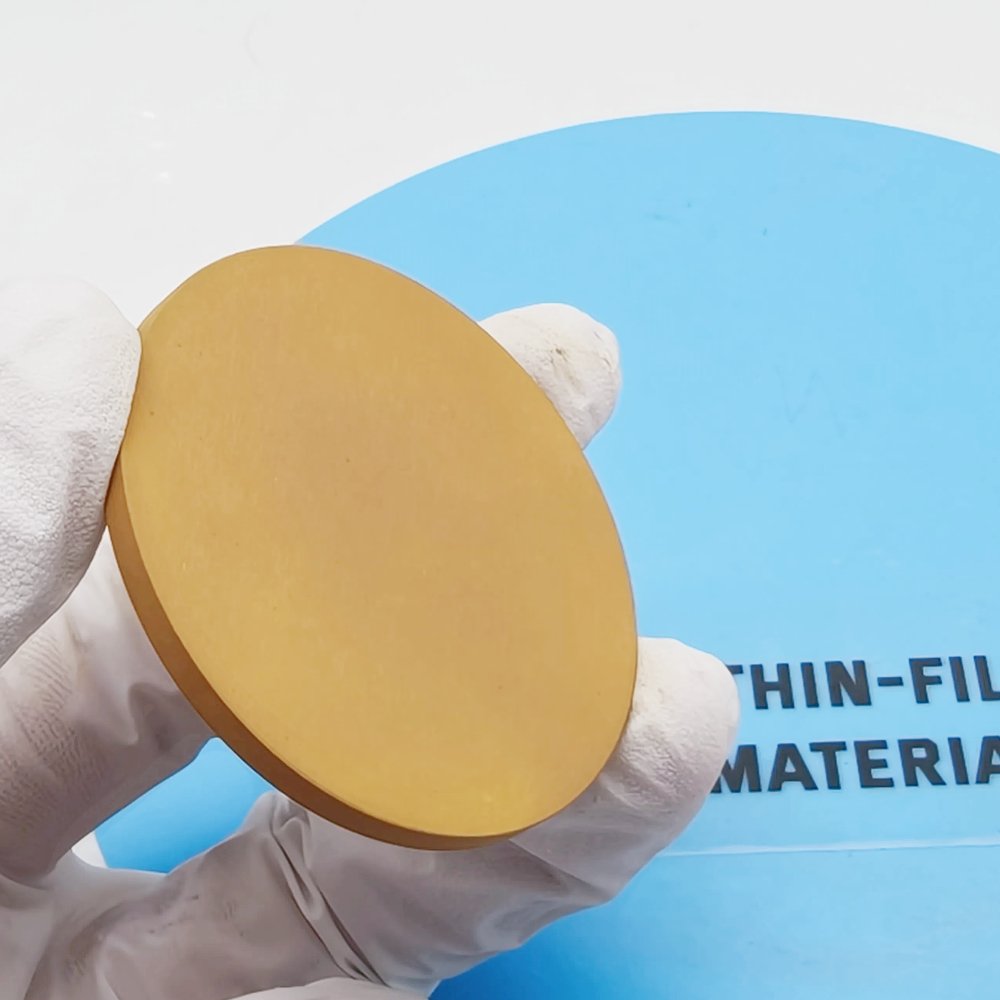

Vanadium Oxide Sputtering Target Packaging

Our vanadium oxide sputtering targets are carefully tagged and labeled on the outside to ensure easy identification and strict quality control. We take special precautions during packaging and transportation to prevent any damage, ensuring that the product reaches you in perfect condition.

Get Contact

TFM offers Vanadium Oxide Sputtering Targets in various forms, purities, sizes, and prices. We specialize in high-purity thin film deposition materials with optimal density and minimal grain sizes, which are ideal for semiconductor, CVD, and PVD applications in display and optics. Contact Us for current pricing on sputtering targets and other deposition materials that are not listed.

Reviews

There are no reviews yet.