Zinc Telluride Powder Description

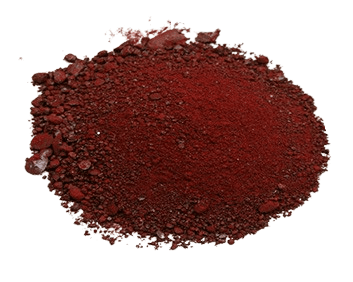

Zinc Telluride (ZnTe) powder from TFM is a high-purity, semiconductor-grade material widely used in infrared optics, thin film deposition, photodetectors, and solar cells. As a II-VI compound semiconductor, ZnTe exhibits a direct band gap of ~2.26 eV at room temperature, making it ideal for optoelectronic devices and infrared (IR) applications.

Zinc Telluride powder is commonly utilized in:

PVD and CVD deposition for ZnTe thin films

Buffer and window layers in CdTe-based solar cells

IR optical coatings and acousto-optic devices

Thermoelectric and photoconductive materials

Quantum dot and nanoelectronics research

TFM supplies ZnTe powder in various purities and particle sizes to meet research and industrial standards.

Zinc Telluride Powder Specification

| Property | Value |

|---|---|

| Chemical Formula | ZnTe |

| Molecular Weight | 192.99 g/mol |

| Purity | 99.99% (4N), 99.999% (5N) available |

| Appearance | Grayish to reddish-brown powder |

| Crystal Structure | Cubic (Zinc Blende) |

| Melting Point | ~1295 °C |

| Band Gap | ~2.26 eV (direct) |

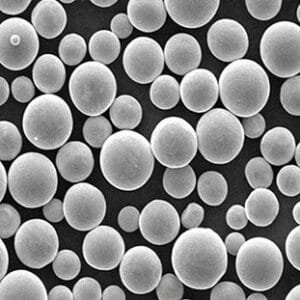

| Particle Size | -100 mesh, -325 mesh, nano-size available |

| CAS Number | 1315-11-3 |

| Density | 6.34 g/cm³ |

Customized particle size distributions and purity levels available upon request.

Applications of Zinc Telluride Powder

Infrared detectors & lenses

Photovoltaic devices and tandem solar cells

Electroluminescent and photoconductive devices

Semiconductor research & nanomaterials synthesis

Handling and Storage

Store in a cool, dry, and inert atmosphere to prevent surface oxidation.

Avoid moisture and acidic vapors, which may degrade material quality.

Use personal protective equipment (PPE) when handling fine powder to avoid inhalation.

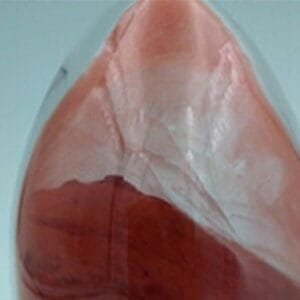

Packaging

Zinc Telluride powder is vacuum-sealed or packaged under argon in anti-static, moisture-resistant containers. Each shipment is clearly labeled with product name, purity, batch number, and net weight to ensure traceability and quality assurance.

Get Contact

TFM specializes in high-purity semiconductor powders such as Zinc Telluride (ZnTe) for advanced research and thin film applications.

Contact us to get pricing, custom sizing, or technical guidance for your application needs.

Reviews

There are no reviews yet.